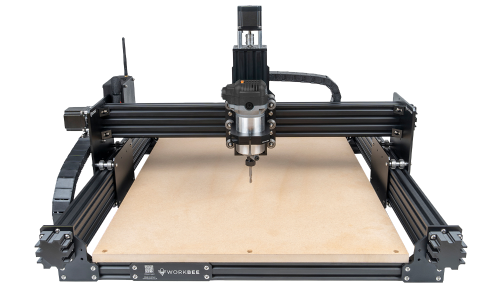

Back in 2017 here at Ooznest we designed and started manufacturing the Original WorkBee CNC Machine . . . .and well, the response from the market was just overwhelming – and since then it has maintained being our flagship machine. We are very proud that the WorkBee has found its way into the workshops of […]

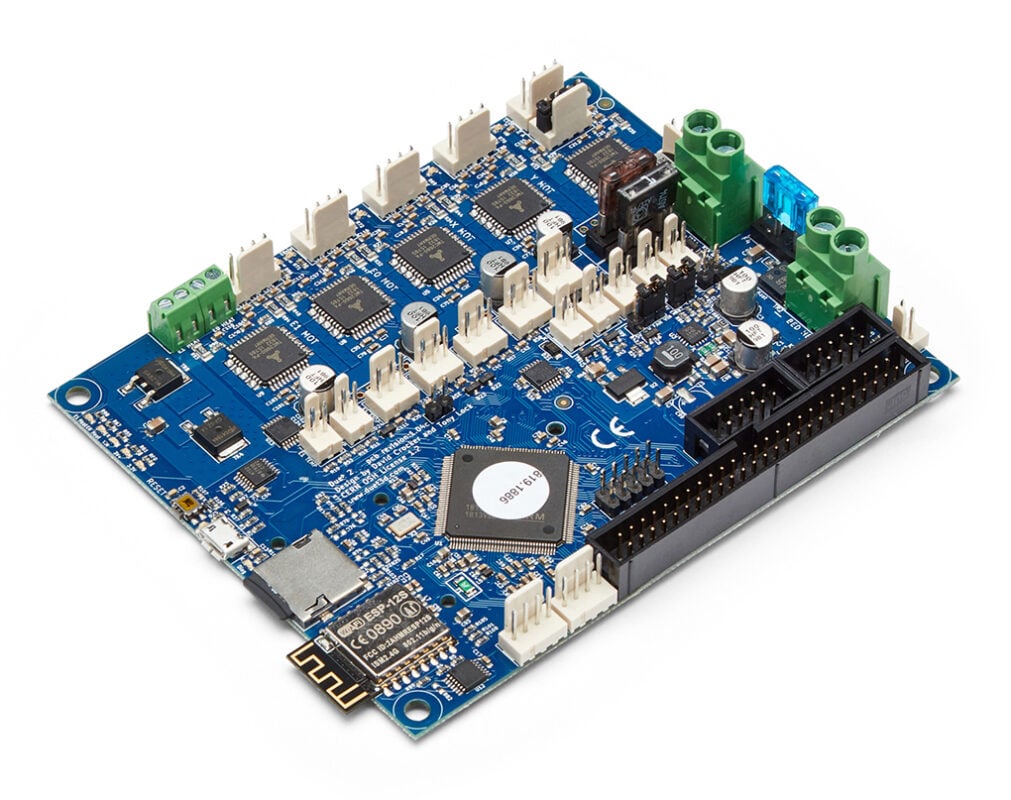

We have some news to share that we are really excited about. The default controller on the WorkBee CNC Machine is changing. The CNC xPro is a good controller and has done us proud over the last 3 plus years. However as it runs GRBL firmware which is already pushing the CNC xPro to its […]

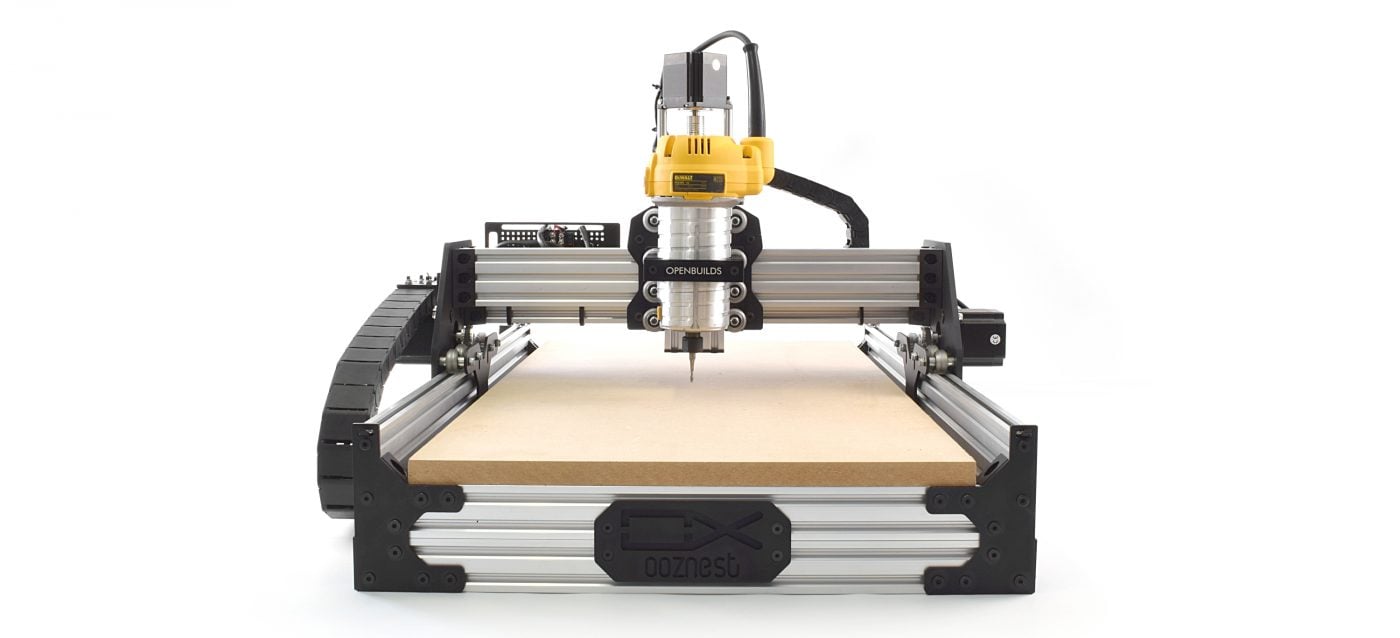

The Past Year We first released the Ooznest OX Mechanical CNC Kit May last year, and it received an extremely good reception. Since then we have sold lots of OX CNC Kits to all reaches of the world, with many happy customers, this has been reflected in the reviews we have received. Since the first […]

The Solution ON Development IVS had a solution and a prototype developed for a stepper motor controller. The result is the uStepper, an integrated Arduino and Stepper motor driver which is mountable on to the back of a NEMA17 Stepper motor. They needed funding to bring this prototype into production, so they headed to Kickstarter. […]

With the recent release of the C-Beam machine mechanical kit on our website, we thought this would be a good chance to show the build of the machine we made for our workshop. All the 3D printed parts that we used on our machine are available via a download link at the end of this […]

It has been a busy couple of months here at Ooznest, with the summer brake stretching us thin and kits keeping us busy, we have been quieter than we would like on the blog and social outlets. Now the summer break is finished we are getting back into full operation, and we should be posting […]

It has been 10 weeks since we released our OX CNC Kit, and for the last 6 weeks we have been flat out shipping orders as quick as we are receiving them. We would like to give a big thankyou to everyone who purchased one of our kits. The response we got exceeded our expectations, […]

AVAILABILITY All C-Beam linear rails, end mounts, gantry plates, and kits, are in stock and available on our website for immediate purchase and dispatch. As many of our customers have come to expect, we offer an extremely quick order turn around, and responsive email/phone support, you can be assured the same applies to C-Beam.