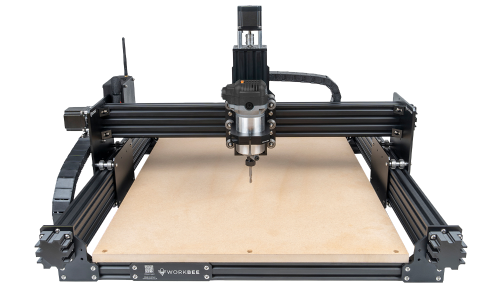

Original WorkBee Enclosure

The panel material is not provided, the required dimensions can be found here: https://learn.ooznest.co.uk/Wiki/Workbee_Enclosure_Critical_Dimensions

CNC Machines are inherently noisy and dusty which makes a dedicated workspace for an Original WorkBee CNC Machine required. Our Original WorkBee Enclosure aims to solve this issue.

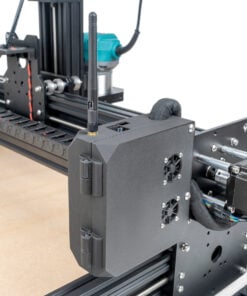

Designed with an aluminium framed extrusion, it allows 6mm thick panel material to be slotted into the extrusion on all sides. This panel material could be completely transparent Perspex to create the wow factor, or very practical 6mm insulated boards for the ultimate in sound reduction.

Running a CNC Machine in a workshop or office is not ideal as a lot of debris and dust is created. Putting the WorkBee CNC Machine inside an enclosure will contain the majority of debris and dust thus providing a healthier working environment.

In normal operation, the machine will have a decibel level of ~80-100db. With an enclosure using 6mm Perspex you would expect a decibel reduction of ~20db, it would be reduced to ~60-80db. If you used MDF as a panel material, you could expect further noise reductions.

All the values above depend on the RPM, endmill, material plus lots of other factors.

Safety is also a huge factor to consider when operating a CNC Machine. With the correct panel material, like polycarbonate, it would safely contain any flying debris from causing harm. As the whole frame is manufactured from extrusion, extra safety measures can easily be added, for example a lockable latch could be added to the two doors, allowing them to be safely locked to prevent unauthorized persons accessing the machine. Door switches are not provided.

The WorkBee enclosure has two front opening doors, combined with a 545mm high opening allows for ample room to access the whole of your WorkBee CNC Machine. As the enclosure only has front opening doors, the enclosure is only available for machines sizes 500x500mm, 750x750mm, 750x1000mm and 1000x1000mm.

The panel material is not provided, the required dimensions can be found here: https://learn.ooznest.co.uk/Wiki/Workbee_Enclosure_Panel_Sizes

ORIGINAL WORKBEE ENCLOSURE SHOWCASE

https://www.youtube.com/watch?v=9uqYnm-j4Io

Documentation

5 reviews for Original WorkBee Enclosure

Only logged in customers who have purchased this product may leave a review.

Richard Wood (verified owner) –

A great enclosure, easy to build and well designed. I used 2 layers of hardboard for the panels with Green Glue to help with sound proofing. The only thing that could be improved upon is to increase the depth a little to allow for dust shoes.

James Silvester (verified owner) –

Well designed and constructed a pleasure to build and adapt to personal configuration

Ravindra Karonde (verified owner) –

There were a few missing screws, but overall I was able to assemble it without any issues. Once assembled and clear panels added the entire thing is pretty heavy and sturdy.

It would have been ideal if the enclosure had been designed to have another opening for wires/hoses

Andy Ramsay –

The fact you can buy the panels yourself whether they be wood or acrylic is a plus.

Mr Andy Gilchrist –

Again well packed, accurately machined, easily assembled and solid construction. will assess its

sound deadening qualities when i have sourced reasonably priced acrylic sheet.