Clearance – HIPS 3D Printer Filament – 1.75mm

WHAT MAKES HIPS DIFFERENT?

WHY CHOOSE OOZNEST MATERIALS?

At Ooznest we live, breath and dream 3D Printing. We use 3D Printers on a daily basis whether it is manufacturing parts for our machines, or just having fun.

Ooznest Materials was launched out of a necessity to bring the widest range of premium materials to every maker at affordable prices. Our filaments are manufactured in Europe to the highest standards, with only premium, not contaminated raw materials.

All our Ooznest Materials 3D Printer Filaments are manufactured to a 0.05mm diameter tolerance. Our filaments arrive vacuumed packed, inside a shrink wrapped box, with an extra special secret treat :). This insures your 3D Printer filament arrives in a pristine condition ready for printing.

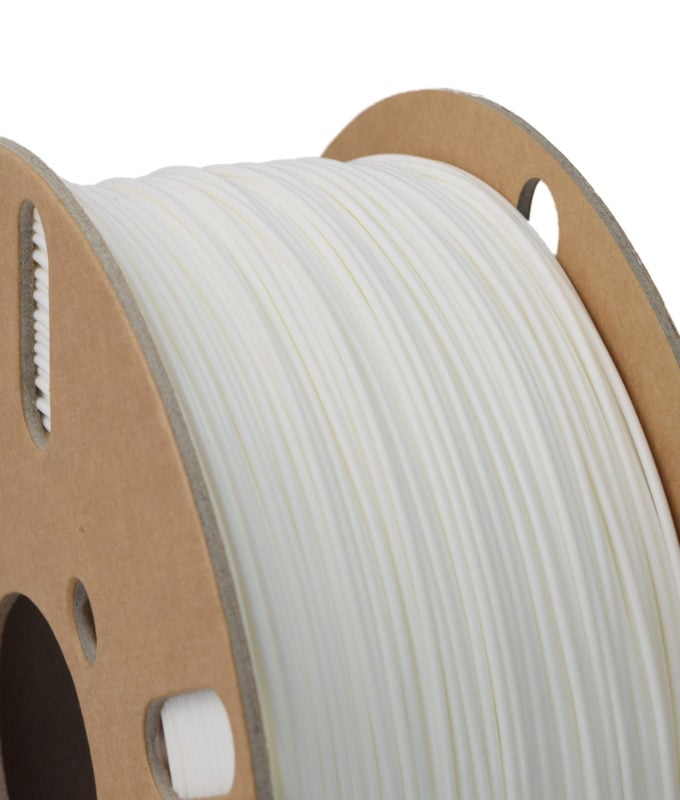

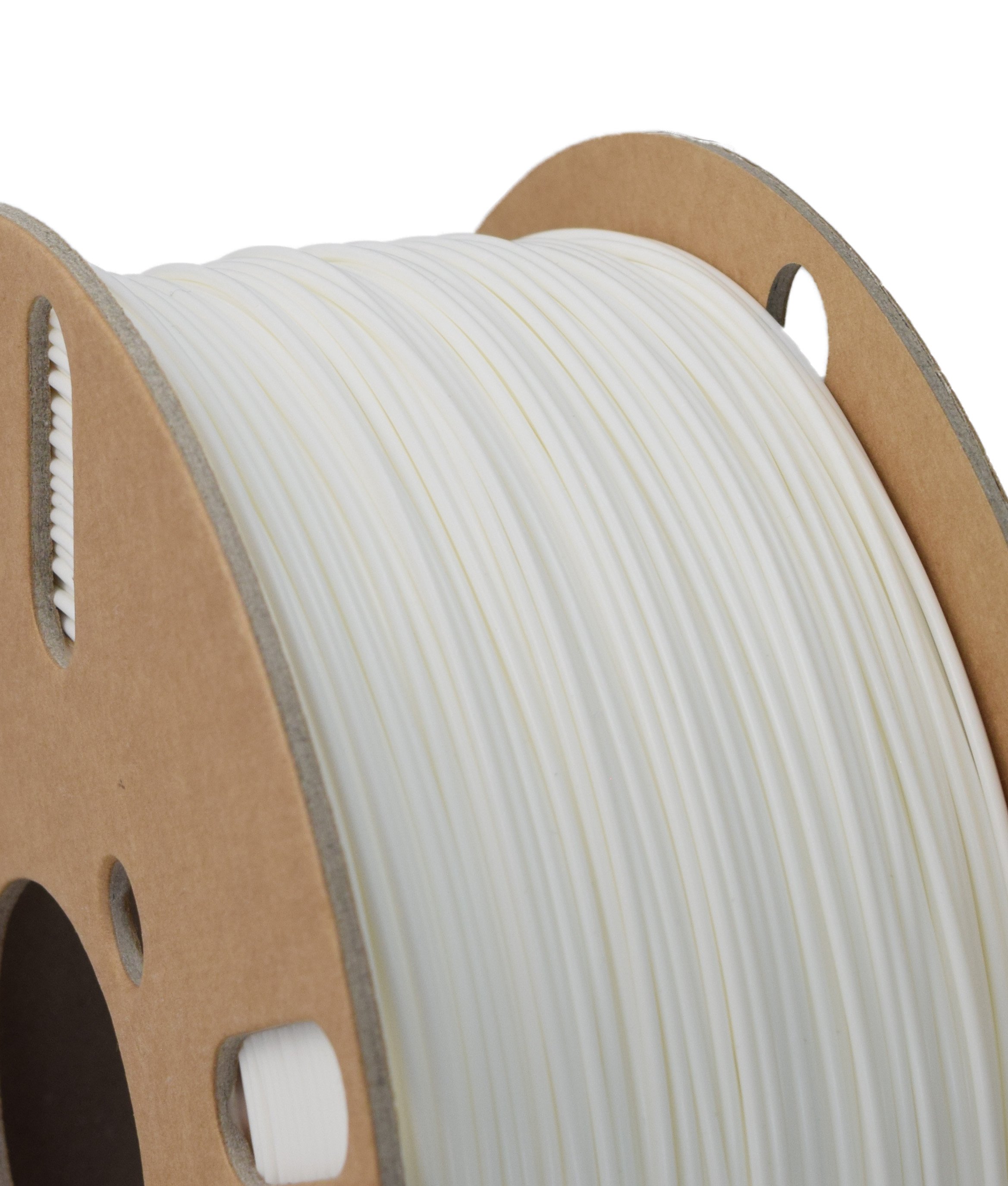

Normally filament is wound onto plastic spools. We recognised that winding 3D Printer filament onto a plastic spool is completely unnecessary. All our Ooznest Material filaments are wound onto a 100% recyclable cardboard spool. Our cardboard spools are extremely rigid, they will not twist, deform, or tear from repeated use.

Not sure if our filament is right for you? Don't worry you can just buy an Ooznest Materials sample and give it a try, we guarantee you won't be disappointed with Ooznest Materials.

We have built a reputation for outstanding customer service, and we plan to keep that with Ooznest Materials. A member of our expert team is available by email or phone, for printing advice, or just a general chit chat. We have a no hassle return or exchange process, if you are happy, we are happy.

Spool Dimensions

Our filament comes on recyclable solid cardboard spools with the dimensions below.

| Spool Width | 78mm |

| Spool Outer Diameter | 200mm |

| Spool Inner Diameter | 56mm |

3 reviews for Clearance – HIPS 3D Printer Filament – 1.75mm

Only logged in customers who have purchased this product may leave a review.

isaac Robson (verified owner) –

I have been printing this stuff using Bambu Studio’s default ABS settings and have been having a good time of it!

Truly minimal warping, produces light weight, impact resistant, easily sandable pieces ideal for model making! Im using a whole lot to make a full suit of Halo: ODST armour!

Robert Koltun (verified owner) –

I bought this product because I needed to print a water resistant part. Being new to 3D printing it took me a bit of trial and error to get the best results. I am sure that I will return to Ooznest again.

Stuart Hills (verified owner) –

Does what it says on the tin, er box, sort of.