Clearance – E3D v6 Copper Nozzle

The E3D v6 Copper Nozzles are manufactured from a high temperature copper-alloy that will not soften until above 500C, this makes them perfectly suited for extremely high temperature applications. With very high thermal conductivity, these v6 copper nozzles make for faster heat up times, and will perform well with most filaments on the market.

The nozzles are also nickel plated. The nickel plating greatly reduces the adhesion of plastic to the metal, meaning they will stay clean, even without a silicone sock. In addition E3D also managed to make them nickel plated internally, making extrusion much easier, more responsive, and less likely to jam.

E3D chose copper because of its high thermal conductivity, it has been hardened and treated to reduce oxidation at high temperatures. This will give faster heat up times and tighter temperature control. Because the copper alloy chosen is temperature resilient, it will not soften or anneal until well after 500C, making it the perfect E3D v6 nozzle for the extreme temperature applications.

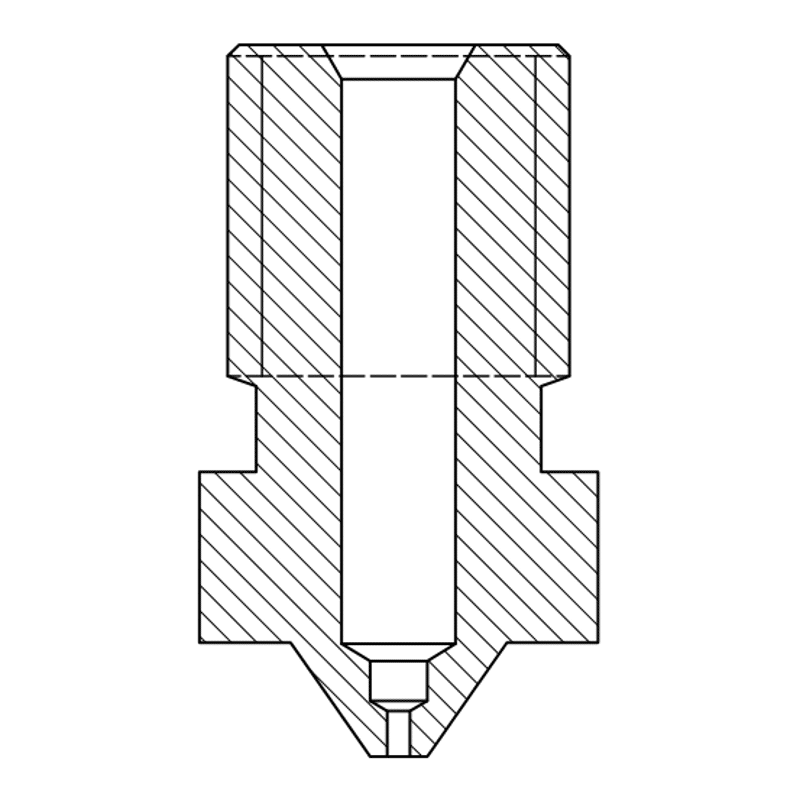

Superior Geometry

The new internal geometry of the E3D v6 nozzle has brought together community feedback and extensive testing. The new nozzles have been designed from the ground up, and have been optimised to reduce back-pressure, ease filament flow, and improve retractions.

The bottom flat surface of the nozzle flattens down the layer of plastic, for each nozzle size this has been customised. On the smaller nozzles, a small tip gives high precision. Whereas on the larger nozzle, a large flat tip improves the finish when printing large layers.

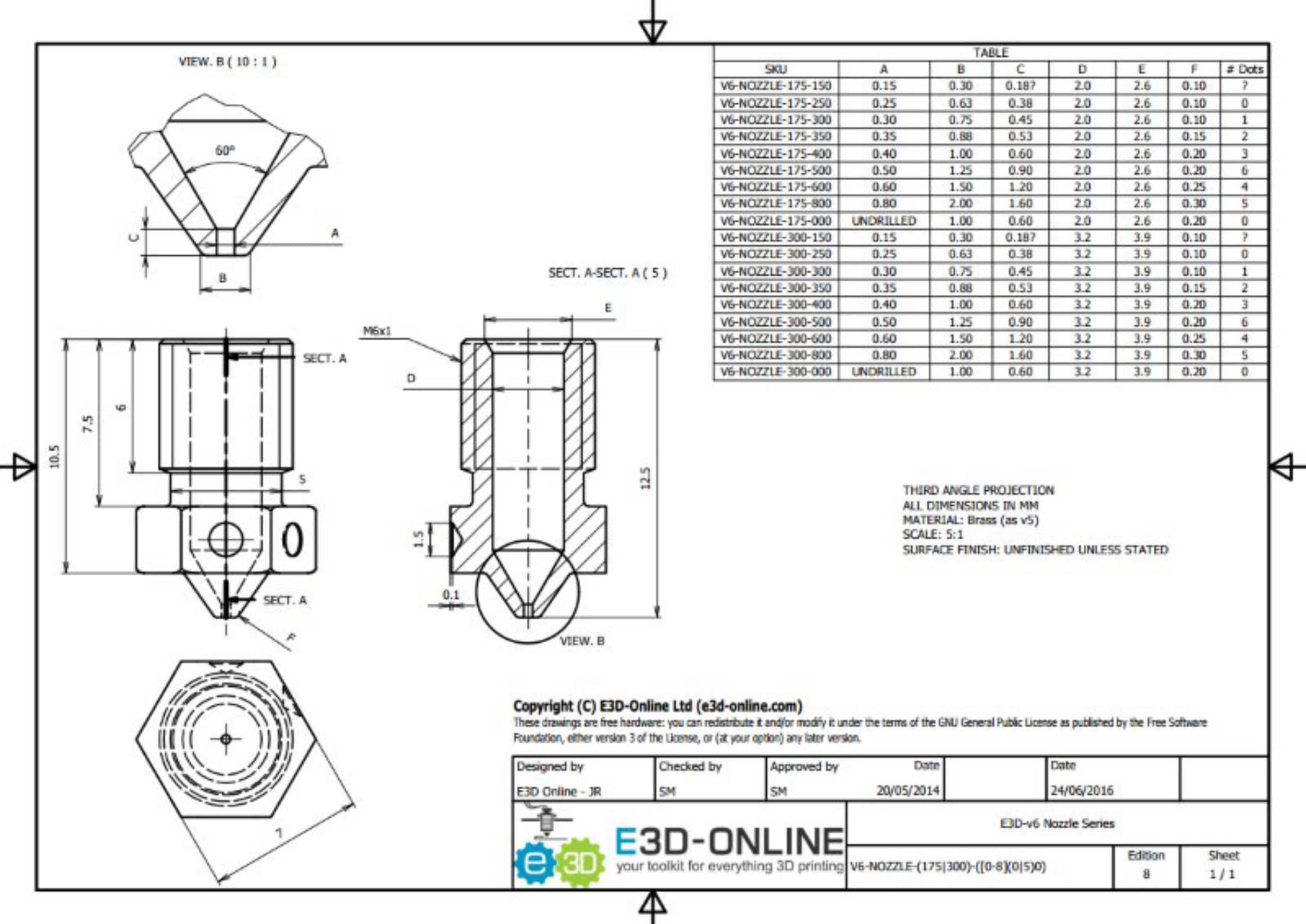

All nozzles are now identifiable by the markings seen on the flats of the hex head. See the table below to identify each nozzle.

NUMBER OF DOTS

DIAMETER

0

0.25mm

1

0.30mm

2

0.35mm

3

0.40mm

6

0.50mm

4

0.60mm

5

0.80mm

Drawing

Documentation

3 reviews for Clearance – E3D v6 Copper Nozzle

Only logged in customers who have purchased this product may leave a review.

Jacques Fortin (verified owner) –

So easy to clean, i will not print without one.

Elfyn Evans (verified owner) –

Good quality.

Ivan (verified owner) –

High quality nozzle gives excellent results