Clearance – E3D Titan Aero Kit

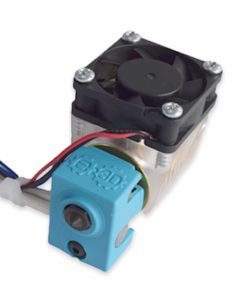

The idea for Titan Aero came after back in March 2016 E3D Launched the Titan extruder, which has become known for its performance and reliability. The next logical step was to integrate a hotend into the Titan and make it into an all-in-one compact hotend-extruder package. The E3D Titan Aero was born.

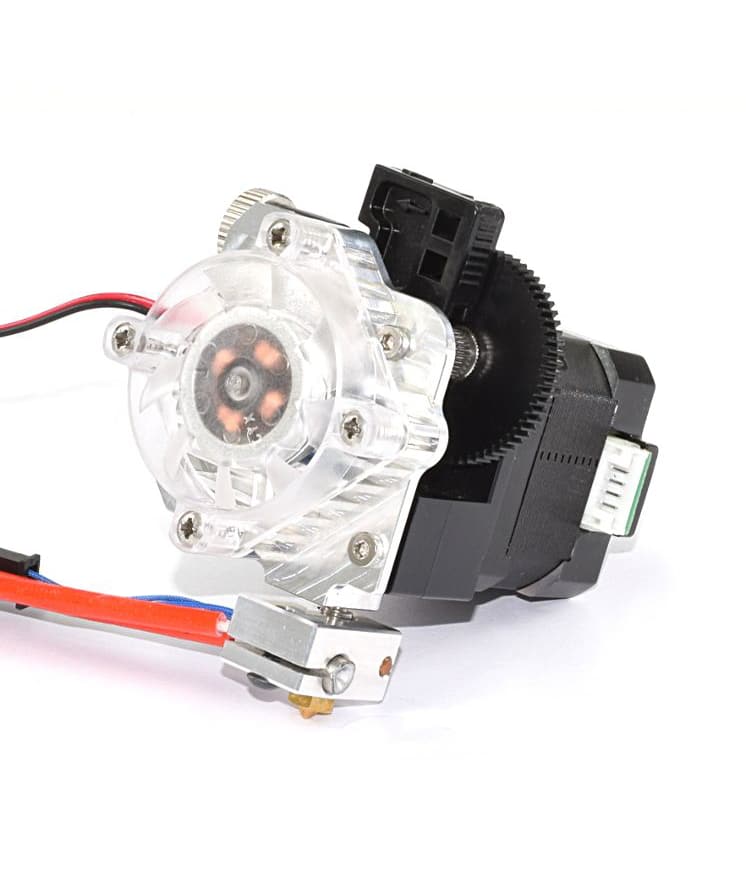

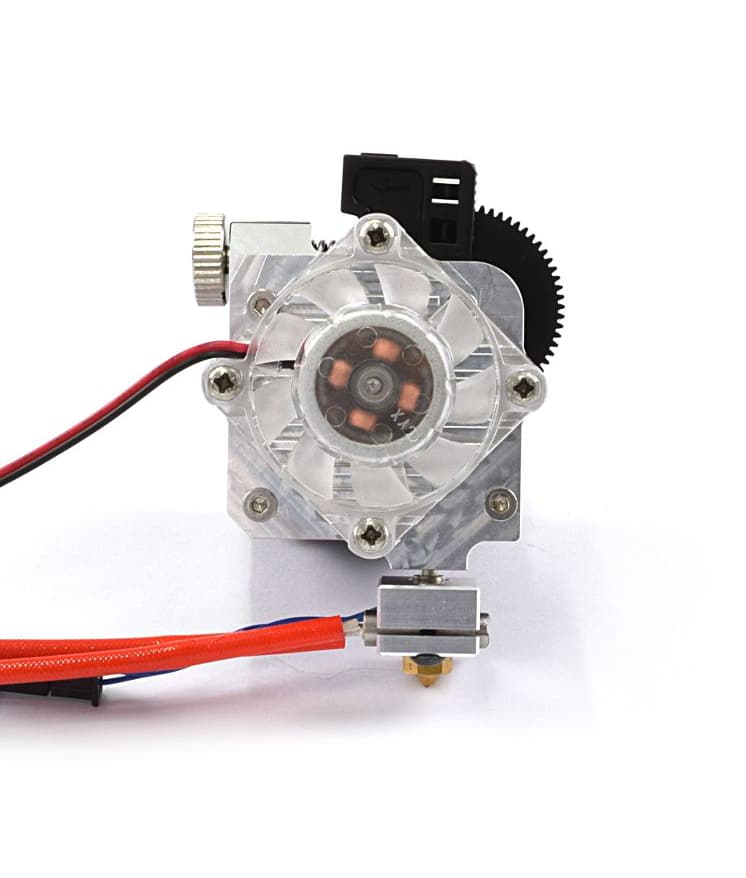

The Titan Aero is a Titan Extruder, but the lid has been replaced with an aluminium heatsink. The heatsink has been carefully designed to give you all the performance of a V6 Hotend and then some. The Titan Aero still keeps the 3:1 gear reduction to provide extreme power. The gear ratio allows for smaller, lighter motors to be used, you will still get the same pushing force with a ungeared lighter motor, than when using an geared large motor.

The Titan Aero is a perfect addition to the E3D ECO System. It still retains the V6 threaded heatbreak, so all the V6 Heater blocks, Sensors, and Nozzles are fully compatible, basically just the same as using a full V6 Hotend.

Compact and rigid

By combining the Titan and V6 into a single package it has made the overall system 25mm shorter, meaning 25mm of greater print height! With a V6 and Titan combo the hotend is simply held in place using a groovemount, but with the Titan Aero because the hotend is fully integrated and bolted onto the extruder it is extremely rigid. The Titan Aero will much more accurately follow the motion system of a 3D Printer, even at very high accelerations.

ACCURATE AND RELIABLE

There is an even greater advantage to the 25mm reduction in length, this means a 25mm shorter filament path. This is important because 3D Printer filament acts like a spring, so when you start to extrude there is a time lag between when the hobbed pulley moves, and when the filament will extrude from the nozzle, the same applies when you finish extruding. Therefore the Titan Aero is a much more responsive system leading to overall better print quality.

The Titan Aero has a fully guided filament path, with no gaps for buckling of flexible filaments. The fully constrained path from extruder to meltzone means flexible filaments are now very easy to print and pain free.

The heatsink on the Titan Aero can dissipate just as much heat as the V6, it has also been rigorously tested in a whole range of environments to insure, that like with the V6, jams are a non-issue.

easy to use and maintain

With an adjustable tensioner system you can easily set the desired tension to a repeatable value. With a quick release lever on the idler, the extrusion can be easily stopped or filament changed.

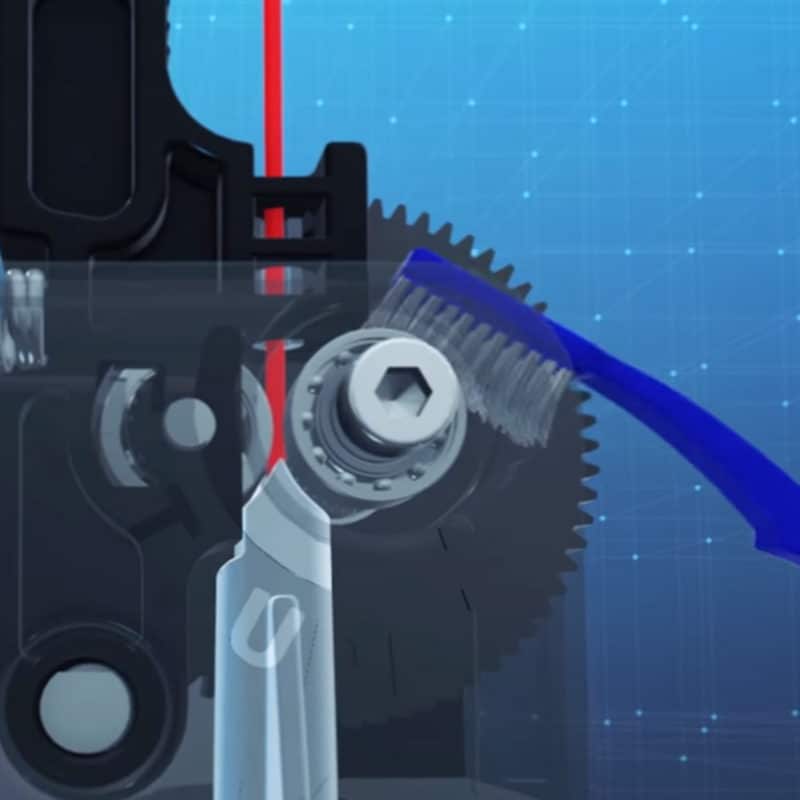

The Titan Aero was designed with maintenance in mind. The hobbed pulley is open, and easily accessible for cleaning with out taking the extruder apart. The shape of the drive gear teeth have been specially designed so filament debris flakes off cleanly. The accessible thumb wheel makes manual extrude, purge, and filament changes a breeze. The inside of the Titan can be accessed within one minute, using only one allen key. It reassembles just as quickly.

WHAT IS INCLUDED

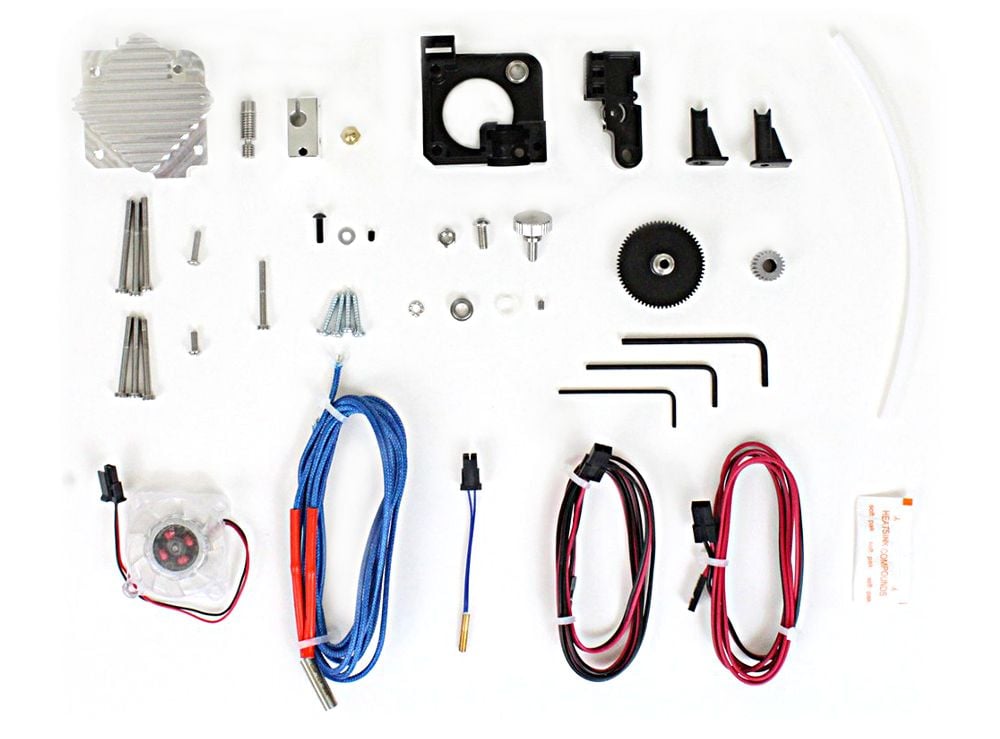

Everything needed to build the Titan Aero Extruder. By default Titan Aero comes with a 0.4mm nozzle and without a motor, mounting bracket or spacer. If bought with a motor, a 2mm PLA printed plastic spacer will be included, unless the mounting bracket is also chosen.

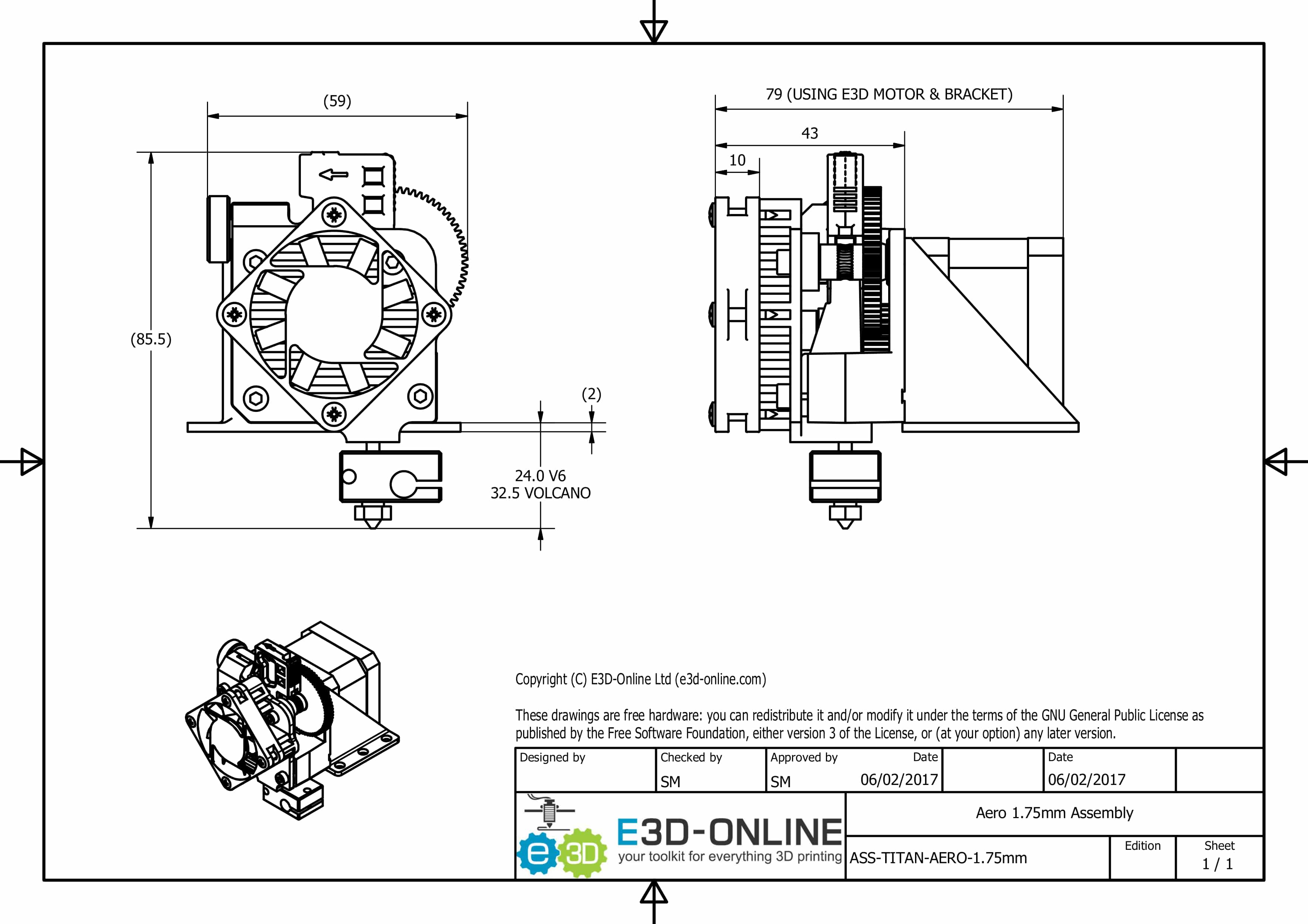

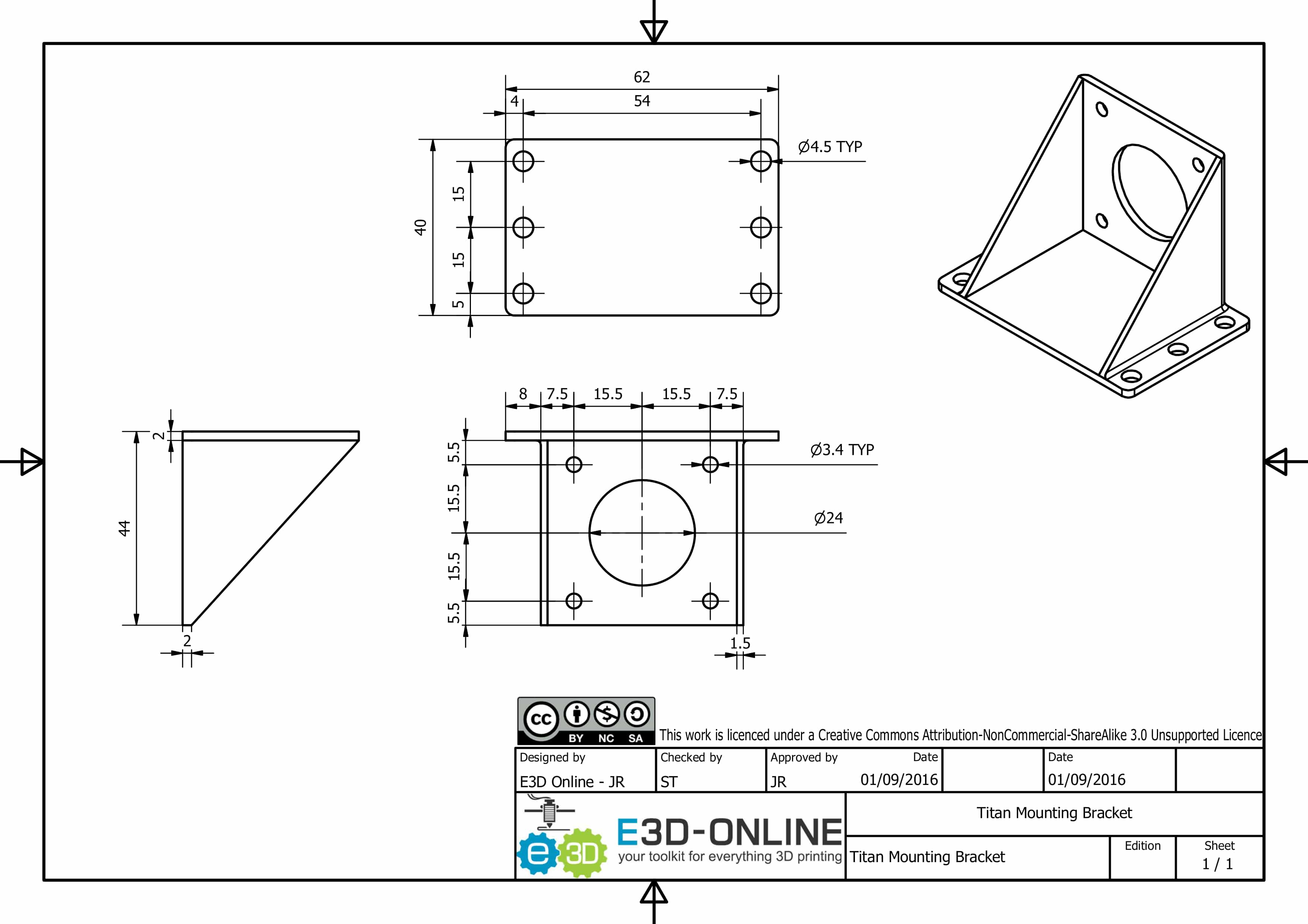

3D Model

Drawings

Documentation

2 reviews for Clearance – E3D Titan Aero Kit

Only logged in customers who have purchased this product may leave a review.

Keith Screawn (verified owner) –

Good kit works well but the motor was faulty, but this was dealt with very reasonably

Mr N G Aucott (verified owner) –

Great product fixed all my hotend woes, very reliable and consistent.

i would/will buy again

a couple of things that i think would make this product from good to excellent.

longer motor screws as the thread engagement is poor.

machine screw fixing for the fan fixing rather than self tappers that again only just engage into the heat sink.