Amana Tool Solid Carbide End Mills – Carbon Fibre

Taxes Calculated at Checkout

Cutting Carbon Fibre & Composites on your CNC Machine requires a specialist type of end mill to get the best possible quality, speed and accuracy. Amana Tool end mills provide exactly this for your projects.

PRODUCT TABLE

Price | SKU | Type | Shank Ø (d) | Cut Ø (D) | Flutes | Length (L) | Cut Length (B) | Coating | |

|---|---|---|---|---|---|---|---|---|---|

| 46264-K No Reviews | Square End | 1/4" 6.35mm | 1/4" 6.35mm | 10 Down-Cut | 3" 76.20mm | 3/4" 19.05mm | Spektra | |

| 46260-K No Reviews | Square End | 1/8" 3.175mm | 1/8" 3.175mm | 10 Down-Cut | 2" 50.80mm | 1/2" 12.70mm | Spektra |

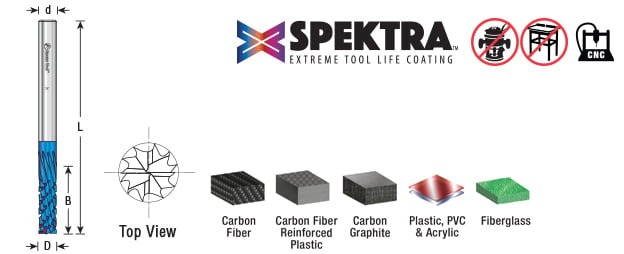

Cutting Carbon Fibre on your CNC Machine requires a specialist type of end mill to get the best possible quality, speed and accuracy of your project. Amana Tool Spektra Coated Square 10 Flute Down-Cut end mills with unique Spektra Coating are designed to produce minimum failures in composites reducing issues with layer separation and loss of mechanical strength.

Amana tools end mills only use the highest quality sub-micron grain carbide. The manufacturing process of Amana endmills takes advantage of an edge processing system which gives the endmill a tool geometry that combines both high abrasion resistant substrates and tactile fluting to create an endmill that shatters the fibres in the composite keeping heat to a minimum. This process will result in clean cuts, minimal chip re-welding, excellent cut finish, and most importantly longer tool life.

These Carbon Fibre cutting endmills from Amana Tools have a specially developed Spektra coating. The Amana Spektra coating provides a much harder cutting edge over standard carbide, increasing tool life. It also has the added benefit of better chip evacuation by reducing the build-up of chips inside the flutes and retain a sharper cutting edge for longer.

Use this End Mill to cut

- Carbon Fiber

- Carbon Fiber Reinforced Polymer (CFRP)

- Carbon Graphite

- Composite Materials

- Fiber Glass

- Fiberglass PCB Board

- Thermosetting Plastics

- Fiber Reinforced Plastic (FRP)

- Glass Fiber Reinforced Polymer – Plastic Materials (GFR)

- Glass Reinforced Plastic (GRP)

- G10 = High-pressure fiberglass laminate, a kind of composite material

- Thermoset Composites

- G10 / FR-4 Glass Epoxy Composite Laminate Material

- G11 / FR-5 Glass Epoxy Composite Laminate Material

- Phenolic

- Phenolic “Garolite” G-7

- Plastic PVC & Acrylic

Note: Blue based color dissipates immediately upon use. nACo® nanocomposite coating will not wear off.

| Mill Size | 1/4 Inch Cut – 1/4 Inch Shank, 1/8 Inch Cut – 1/8 Inch Shank, 1/16 Inch Cut – 1/8 Inch Shank |

|---|

Only logged in customers who have purchased this product may leave a review.

Related products

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Reviews

There are no reviews yet.