Clearance – E3D Lite6 Hotend Full Kit

From: £39.36

Ex VAT: £32.80

Taxes Calculated at Checkout

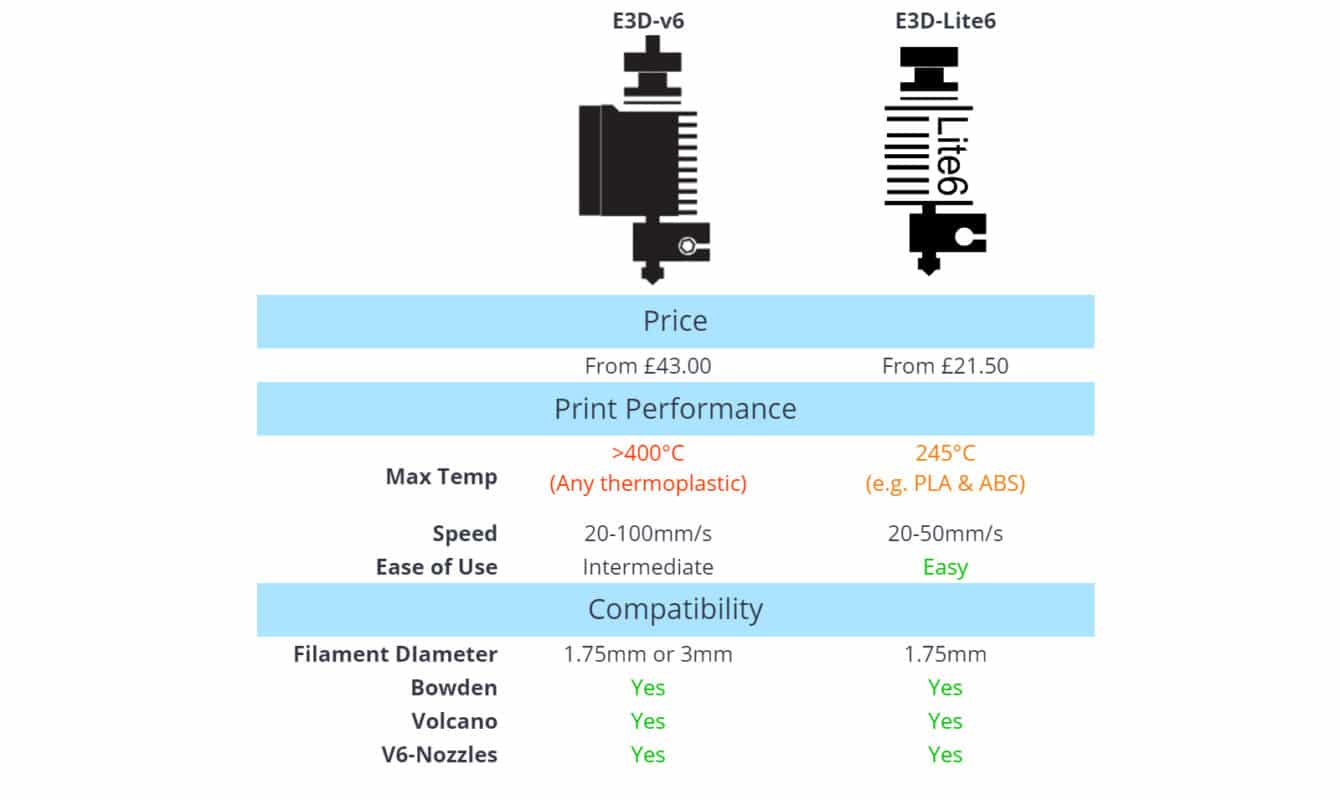

A high temperature all metal hotend such as the E3D v6 is not needed by everyone, the Lite6 fills this gap. The E3D Lite6 is a reliable high quality 3D printer hotend that is very low cost, and meets the budget for anyone just starting out in 3D printing.

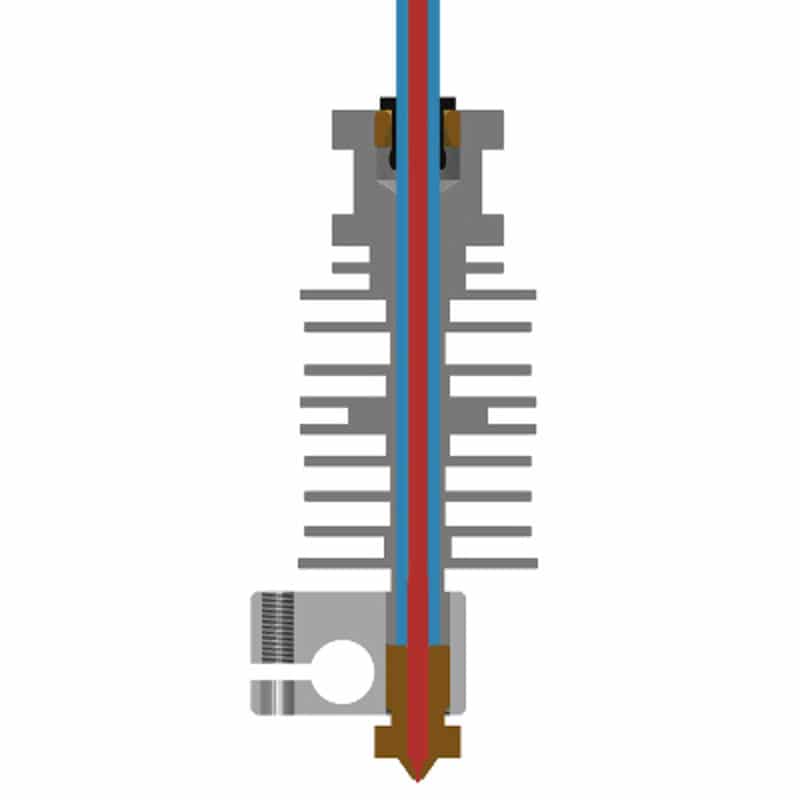

The Lite6 is a mostly metal design, it uses a PTFE Liner to bring costs down. This allows it to compete in the same price range of all the low cost hotends, including many of the clones.

Lite6 is the v6’s little brother. It is a conservative hotend, which is great for beginners or those on a tight budget.

PRINT EVERYDAY MATERIALS

Because of the PTFE liner, the maximum operating temperature of the E3D Lite6 is 240ºC. This means the E3D Lite6 hotend cannot print high performance materials like nylons, polycarbonates, or carbon fibers. However the Lite6 is better positioned to print every day materials like ABS & PLA without skipping a beat. The full length PTFE liner also allows the Lite6 hotend to excel when printing flexible filaments.

Compared to the E3D v6, the Lite6 has a shorter melt-zone, this reduces the maximum print speed. However the Lite6 is still capable of printing at speeds found on the majority of machines on the market. The Lite6 is compatible with the complete E3D ECO System, so you can easily upgrade to Volcano for super quick 3D printing.

To keep costs down the Lite6 is only compatible with 1.75mm diameter filaments. 1.75mm is quickly becoming the standard, so this will meet the needs of most users. Like the E3D v6, the Lite6 hotend uses an integrated bowden coupling system, enabling it to be used as direct or bowden 3D printer hotend straight out of the box.

TOP CLASS RELIABILITY

The Lite6 is incredibly tolerant to abuse, the metal construction makes it near impossible to break from accidental crashes. No PEEK can be found on the Lite6, making it very resistant to overheating accidents. If the hotend is overheated only the PTFE liner will be damaged, luckily these only cost £0.33. Parts made out of stainless steel are nearly impossible to damage, and have no chance of overheating with the supplied heater.

Many parts from the v6 hotend are used on the Lite6, these have been tried and tested many times before. The nozzles and heater blocks have been highly optimised, this means v6 components are used in the most important areas of the Lite6 3D printer hotend.

SILICONE SOCK

A silicone sock is included with each E3D Lite6 kit. The silicone sock is manufactured from a heat resistant non-stick silicone, and will repel the build up of molten plastic.

The silicone sock will dramatically increases temperature stability. The temperature of the heater block can be more tightly controlled, even with aggressive active cooling. Radiant heat from the heater block will no longer be a problem to your prints.

The life time of the Silicone socks varies depending on what material you are printing. With abrasive materials they should last at least 100+ Hours. With less sticky materials and gentle use, they could have an infinite life.

LOW COST DOESN’T MEAN LOW QUALITY

By adopting a PTFE liner the high tolerance thermodynamic control seen on v6 can be relaxed. By still using the E3D v6 nozzles and being mostly metal, no print quality is lost. The PTFE not only reduces manufacturing tolerances but makes the Lite6 hotend highly reliable.

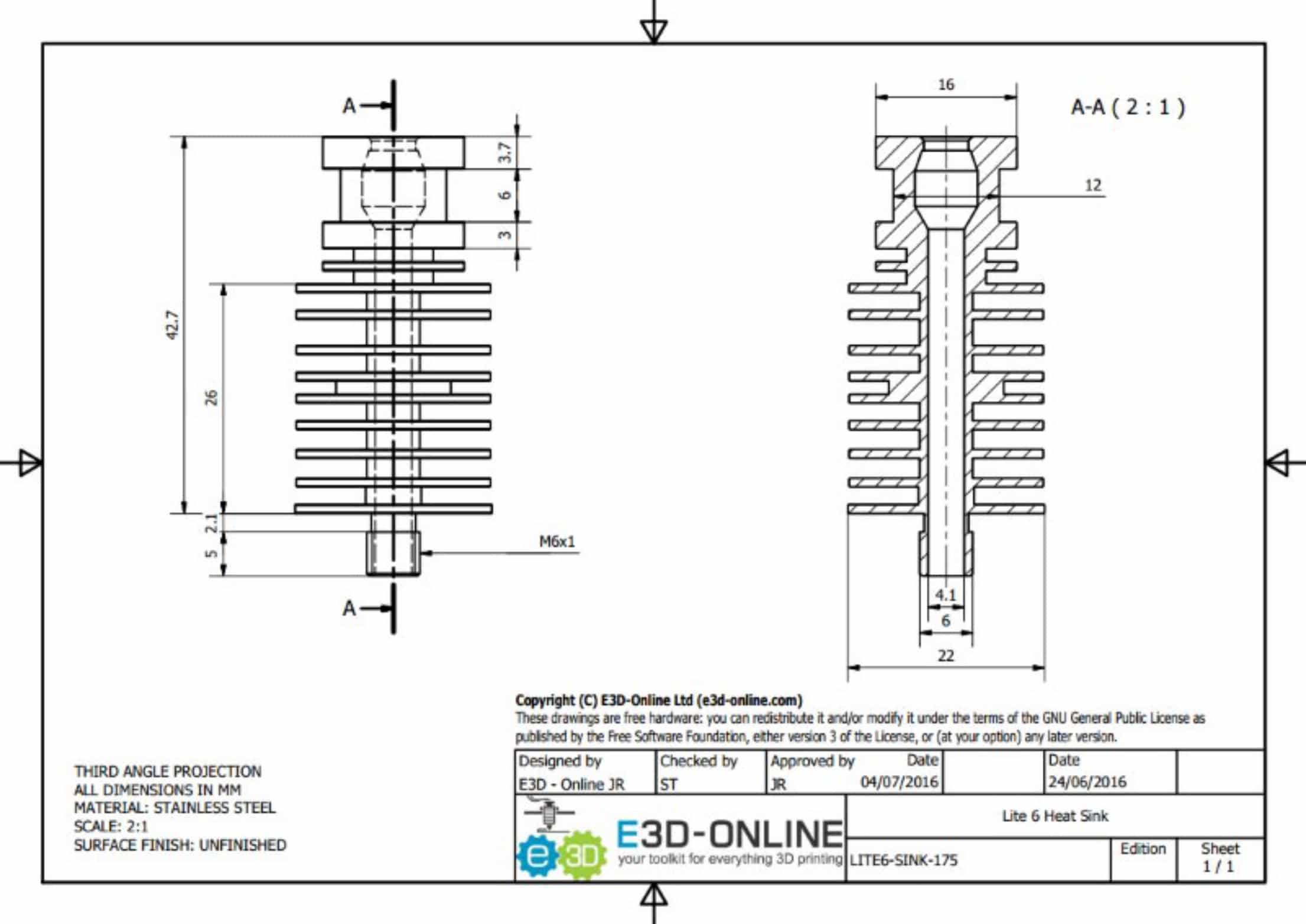

Using a stainless steel heatsink is nearly unheard of, but the Lite6 uses exactly that. The single piece stainless steel heatsink and heatbreak on the Lite6 hotend replace the 2 piece system seen on the v6 which are extremely expensive to manufacture. Stainless steel is heavier than aluminium, so the Lite6 is 22g heavier than the v6.

QUICK ASSEMBLY AND EASY MAINTENENCE

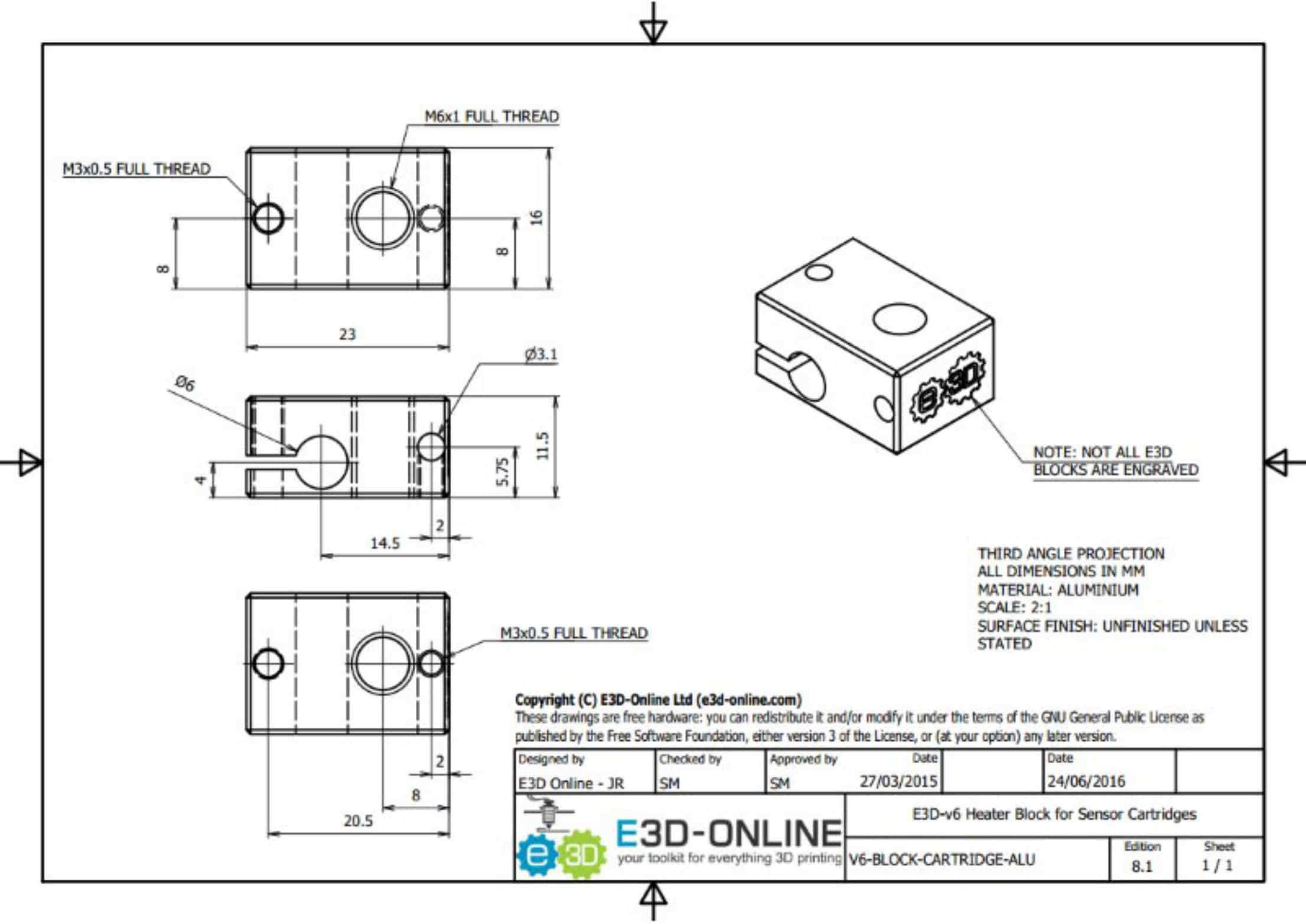

The usual pain experienced when assembling a 3d printer hotend has been completely removed with the Lite6. E3D have developed a new cartridge based thermistor system, these are simply held in place using a grub screw, no kapton tape, no fuss. The new cartridge sensors are easier to maintain, more robust, and tolerant to abuse. Other cartridge sensors are available, PT100 & K-Type Thermocouple, these can be quickly swapped out with the new design.

Other parts of the 3D printer hotend screw together and the fan duct simply clips into place, and can be orientated in any direction around the heatsink.

E3D ECO SYSTEM

The E3D Lite6 is the perfect first stepping stone for beginners into the world of 3D printing. The Lite6 shares its core components and dimensions with the E3D v6 making an incredibly simple upgrade path.

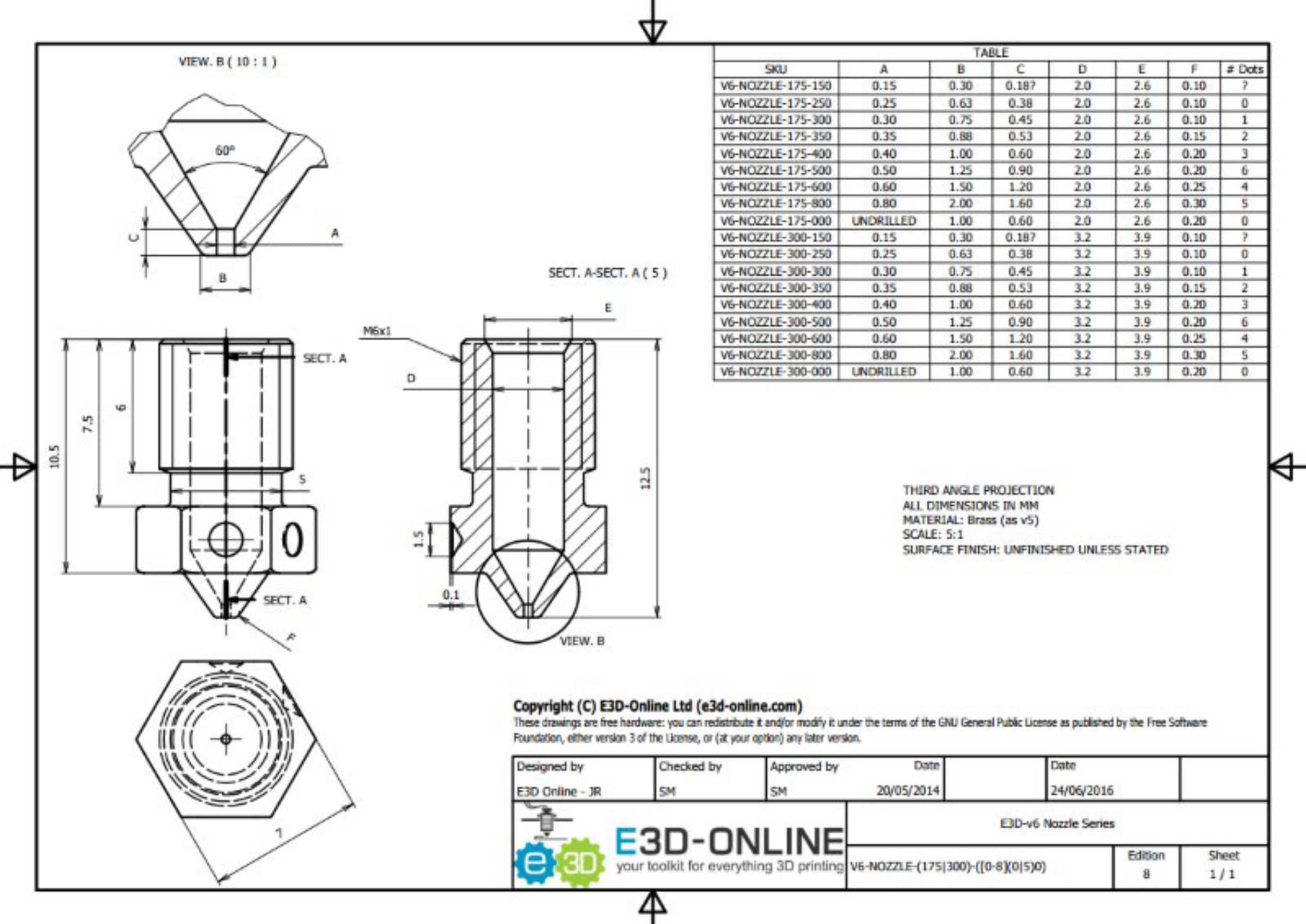

By using the Lite6 you get access to the whole range of E3D products. The E3D Lite6 is compatible with a wide range of nozzles sizes, from super small 0.25mm to the large 0.8mm. The nozzle geometries have been tailored to improve fine details with smaller nozzles, and quicker large extrusions with the bigger nozzles.

Not only are brass nozzles available, but also hardened steel nozzles, these allow for wear free abrasive material printing.

A Volcano heater block can also be attached to the e3d v6 heatsink for super fast large format 3d printing.

WHAT IS INCLUDED

1 x E3D Lite6 Hotend, with a 0.4mm brass nozzle.

1 x 30W Cartridge Heater to chosen voltage.

1 x Thermistor Sensor Cartridge

1 x 30x30x10mm DC Fan to chosen voltage

1 x Red Fan Duct (Sometimes will be blue)

1 x Fixings Kit

1 x Silicone Sock

(When Chosen) Bowden Kit Which Includes:

1 x Extruder Screw Coupler

800mm x PTFE Tubing

(All sized appropriately)

With the 1.75mm direct version, 120mm of PTFE is supplied to go inside the hotend.

| Voltage | 12V, 24V |

|---|---|

| Drive Type | Direct, Bowden |

Drawings

Documentation

6 reviews for Clearance – E3D Lite6 Hotend Full Kit

Only logged in customers who have purchased this product may leave a review.

Related products

Taxes Calculated at Checkout

Ex VAT: £3.80

Taxes Calculated at Checkout

Ex VAT: £111.00

Taxes Calculated at Checkout

Ex VAT: £50.00

Taxes Calculated at Checkout

Ex VAT: £50.00

Taxes Calculated at Checkout

Ex VAT: £4.20

Taxes Calculated at Checkout

Taxes Calculated at Checkout

Ex VAT: £6.50

Taxes Calculated at Checkout

Tom Barton (verified owner) –

Really good hotend impressed so far

customer (verified owner) –

Easy to put together and the print quality is amazing could not be happier thanks

Josip001 (verified owner) –

Amazing hotend. everything precise

John Marshall (verified owner) –

Brilliant sorted my clogging problem..

tom shears (verified owner) –

Easy to fit and works great.

Mr Daniel Barker (verified owner) –

Good quality parts with all screws and hardware necessary for assembly.