Blog

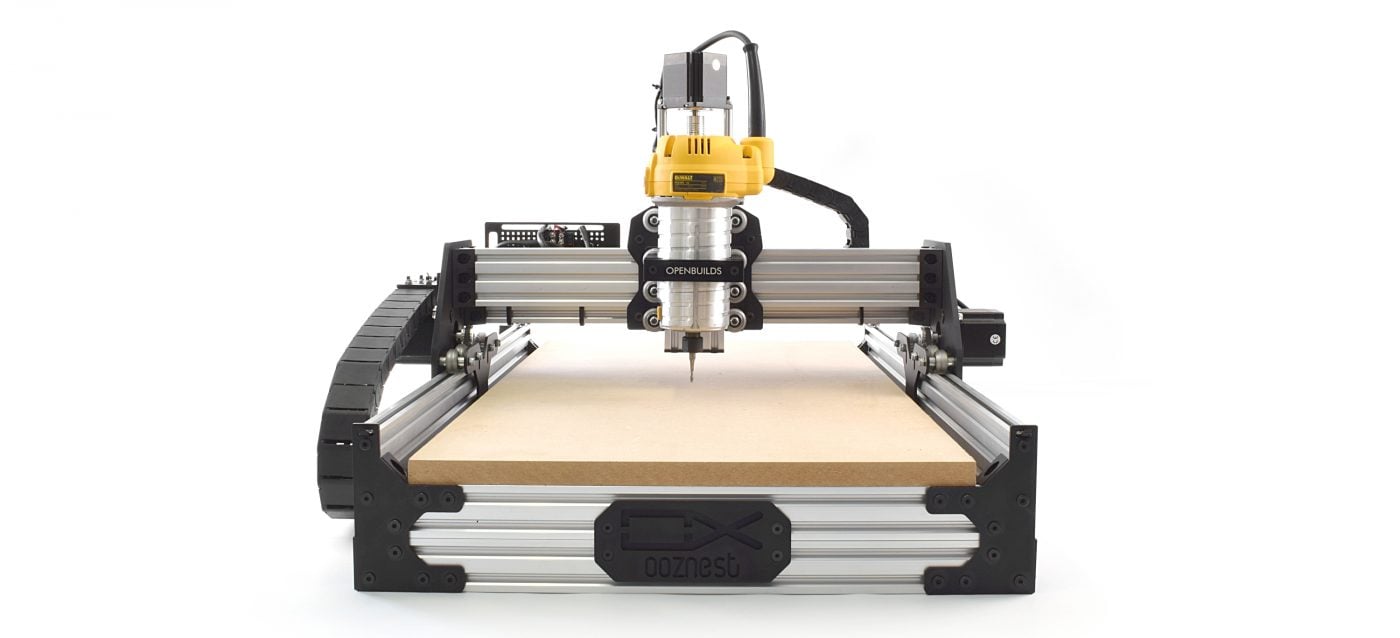

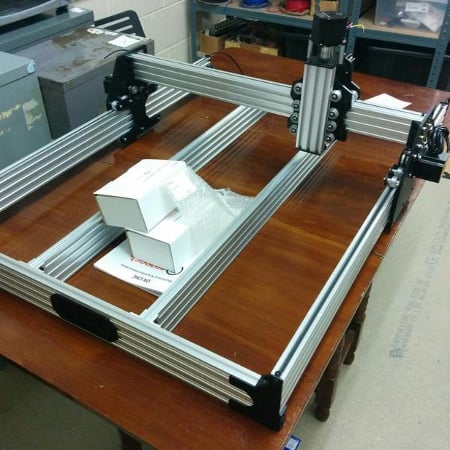

OX CNC Full Kit Development

The Past Year

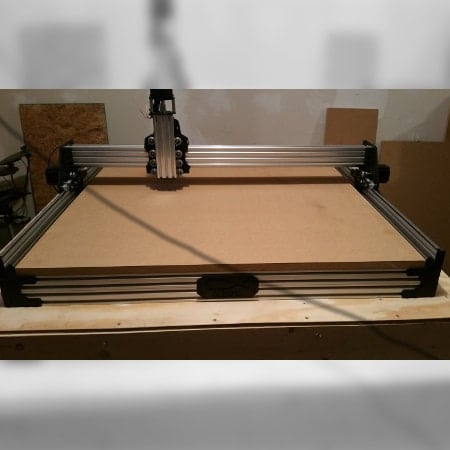

We first released the Ooznest OX Mechanical CNC Kit May last year, and it received an extremely good reception. Since then we have sold lots of OX CNC Kits to all reaches of the world, with many happy customers, this has been reflected in the reviews we have received.

Since the first month we started selling the OX CNC Kit, we received one constant request from interested customers, this was for a full kit. We sold all the main parts to get a working machine, but sourcing all the misc wires, mounting the controller, and keeping the wires tidy can be a pain and very time consuming. Listening to these requests, we started straight away working on a full kit. The full kit had to solve all the pain points people would face when setting up the machine. These included wiring the PSU, mounting the controller, keeping the controller cool, safely routing the wires. It took longer than expected, but we are happy to say that the full kit is finally available!

The Full Kit

The full CNC kit builds upon our existing mechanical kit and includes everything you need to build a working CNC Machine apart from the router and spoiler board. For the controller we chose to use the CNC xPro, we have been selling these for as long as the OX Mechanical Kit, and they have proven to be very popular. The xPro is a GRBL Based controller and has 4 built in DRV8825 stepper drivers which have enough power to each run a 175oz NEMA23 Stepper Motor. We designed a plastic plate that holds the xPro to the back of the x-gantry, with this we also designed a mount which sits on top of the xPro, that mounts 2 x 24V 30mm cooling fans.

The xPro can be powered from an ATX PSU, however these are only available in 12V, and we wanted to run the machine at 24V for better motor operation. So we decided to use a standard 24V 350W switching power supply. These can be untidy and unsafe power supplies to use. So we decided to design a 3D Printed plastic cover, to which we mount a switched IEC Inlet, LED Volt Meter, and XT60 Power Outputs.

The power supply will sit at the back of the machine, therefore we needed a safe way to get the power wires from the power supply to the moving gantry. Cable carriers were needed. Again we designed 3D Printed mounts to hold 30x15mm cable carriers on the both the X & Y Axes.

The optional router mount is capable of holding any 71mm outer diameter router. Models that meet his criteria are the Bosch Colt and DeWalt 26200.

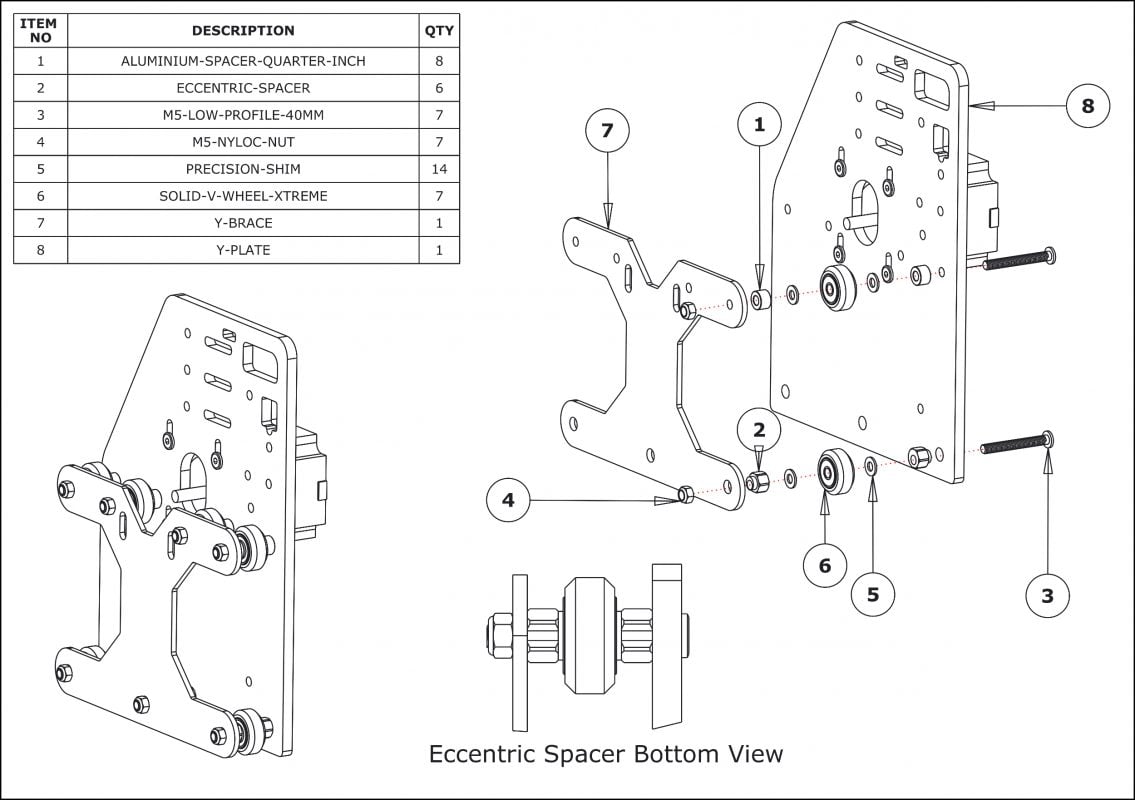

Manual

With our Mechanical CNC Kit we provide a printed manual guiding you through the assembly. We wanted to do the same for the full kit. So we spent countless our creating a manual which can be started straight after completion of the mechanical manual. This manual will guide you through cable carrier mounting, PSU assembly, controller setup, and most importantly software setup. Our latest manual continues the tried and tested format of IKEA’ske diagrams with written instructions.

We hope the above has given you some insight into the background development of the full kit and as always welcome any suggestions!

I purchased OX CNC sometime Jan. 2017. What sort of updates can I still do with my CNC machine?

Hi Bayu,

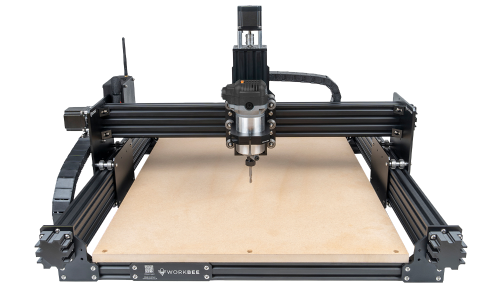

Thanks for your comment, I am afraid we do not have any updates for the OX as we designed the WorkBee to be its replacement.

You could potentially switch to your WorkBee Controller:

Controller – https://ooznest.co.uk/product/original-workbee-replacement-duet/

Case – https://ooznest.co.uk/product/original-workbee-controller-case-kit/

Wires – https://ooznest.co.uk/product-category/workbee-cnc-machine/workbee-replacement-parts/

Thanks

Hi Ryan,

I purchased OX CNC sometime Jan. 2017. What sort of updates can I still do with my CNC machine?

Is the WorkBee electronics and firmware compatible with my OX CNC?

Kind Regards,

Jerome

Hey, did you want to email into sales@ooznest.co.uk One of the customer service team will be able to answers all your questions 🙂

Hi

I understand that you are slling the OX kit any longer but having just purchased the plates in your sales and with an intention to buy the rest over the next few months – budget permitting can i still obtain the manual

Yup, the manuals can be downloaded here: https://openbuilds.com/builds/ooznest-ox-cnc-machine.2084/

Hi Ryan,

I would like to purchase the OX CNC Full Kit, yet the link you provided unfortunately does not work.

Is the Full Kit still available? Where can I get it?

Thank you so much!

Kind regards

Matthias

Hi, I am afraid the OX Full kit is no longer available. We just sell the WorkBee full kit now: https://ooznest.co.uk/product/workbee-cnc-full-kit/