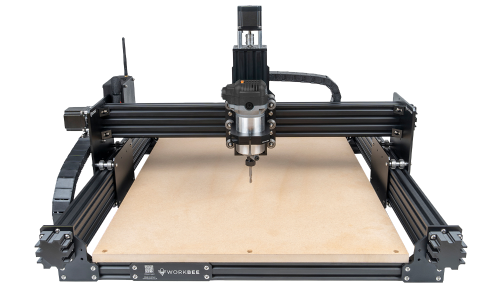

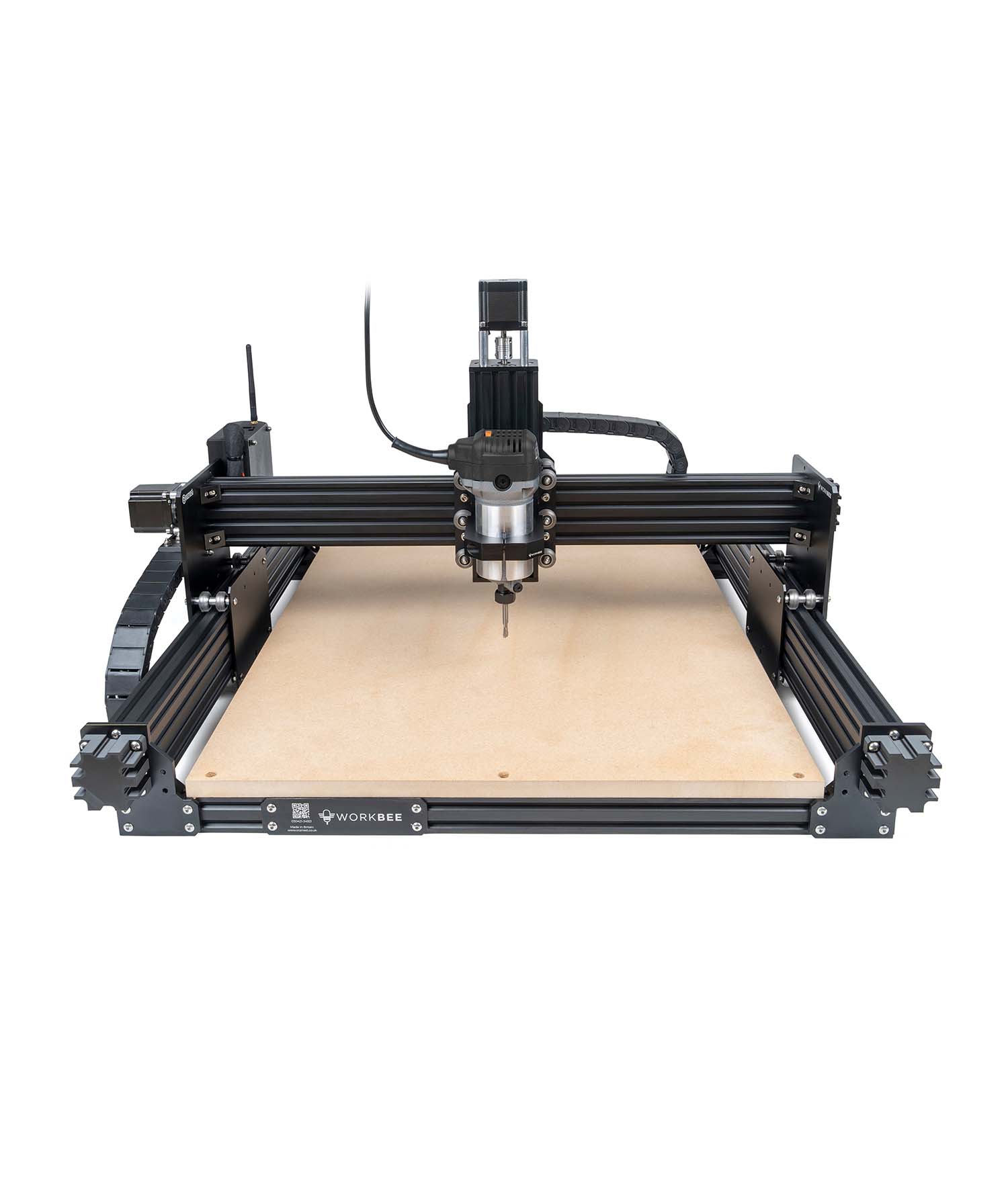

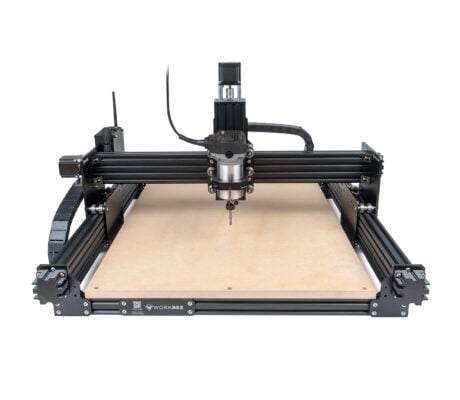

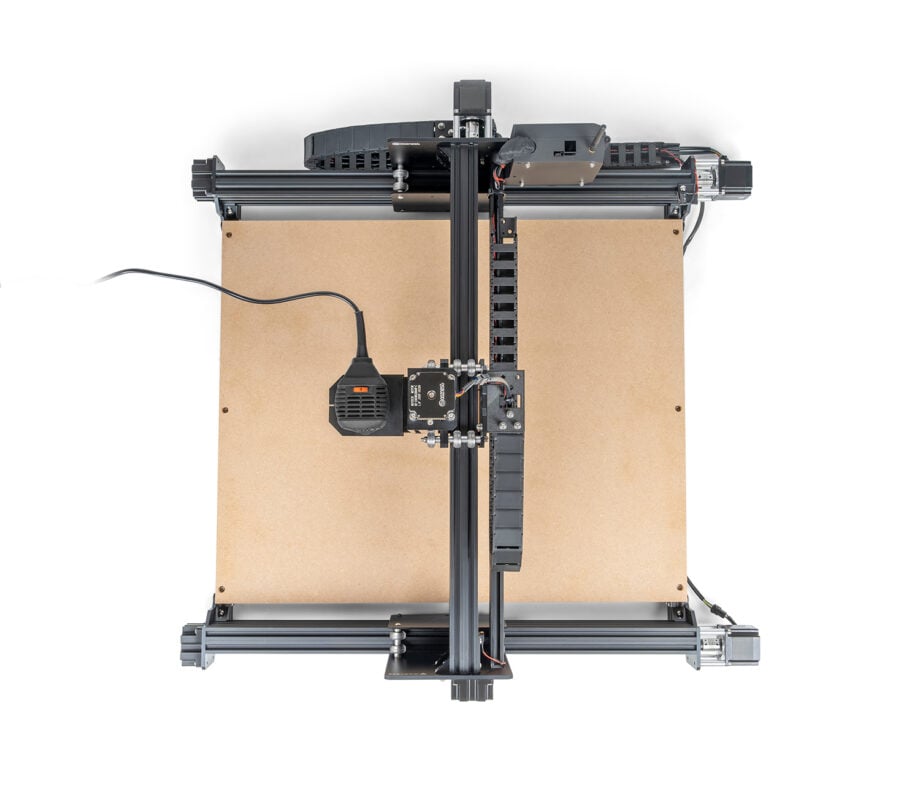

Original WorkBee Z1+ CNC Machine

WorkBee Z1+ CNC Router Machine

Make projects like engineering parts, signs, toys and furniture... in fact with your Own CNC Router you can make anything you can imagine without leaving the workshop!

The WorkBee Z1+ is an Easy and Capable self-build CNC Router.

• UK Customer Support • 1 Year Warranty (All Parts) • Thousands Machines Sold

• British Designed & Manufactured • 10 Years Manufacturing Experience

accessory bundles

Every WorkBee Z1+ includes as standard the aluminium extrusion frame, motion & transmission system, control system, power supply, emergency stop, control interface, two router bits, and manuals. All electronics are pre-commissioned, and the machine is ready to build with only simple hand tools.

To start cutting with your WorkBee, you’ll need a Router Head and Router Mount. Our accessory bundles include these must-have items – plus more

Essentials Bundle

Add the Essentials Bundle to get set up at the lowest cost.

WorkBee Router Head

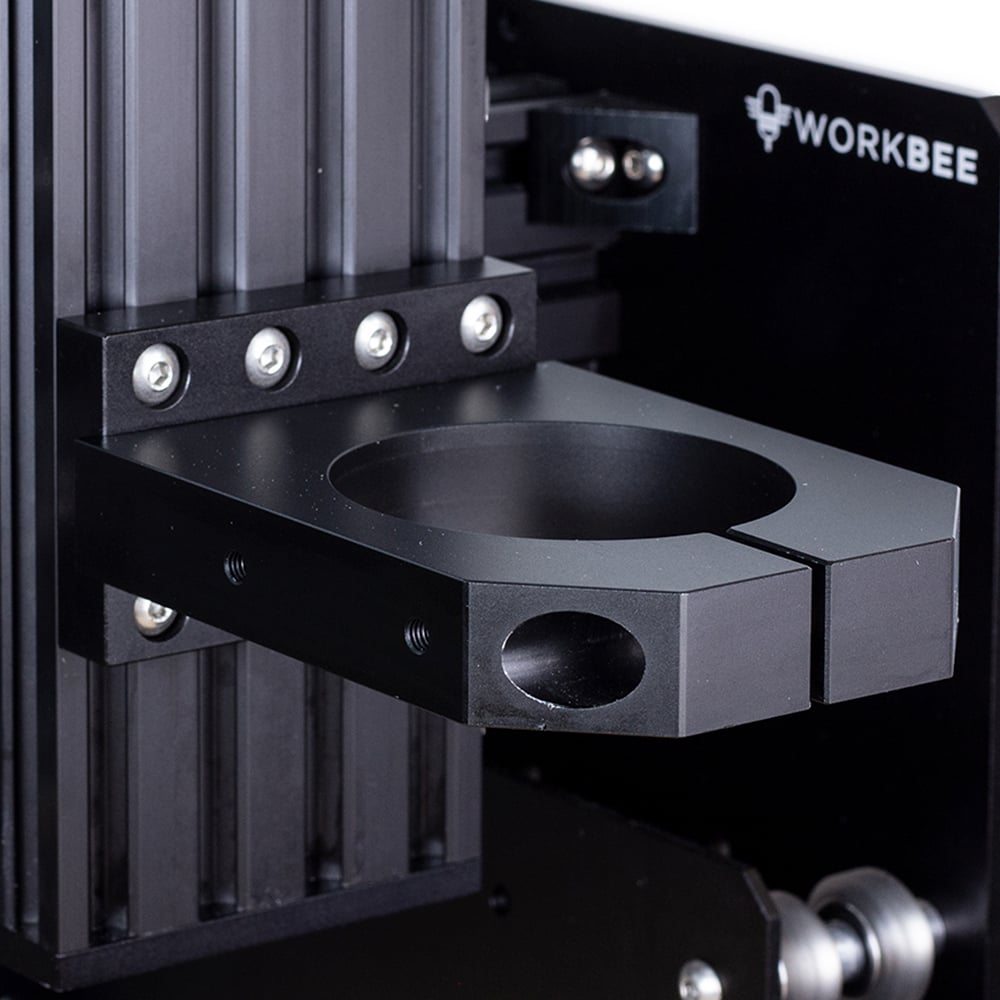

65mm WorkBee Router Mount

WorkBee XYZ Touch Probe

1/4″ ER11 High Precision Collet

1/8″ ER11 High Precision Collet

Advanced Bundle

Add the Advanced Bundle to explore more of the machine’s capabilities and keep your workspace clean with the Dust Shoe.

WorkBee Router Head

65mm WorkBee Router Mount

WorkBee XYZ Touch Probe

Dust Shoe

General Purpose Starter Router Bit Kit

1/4″ ER11 High Precision Collet

1/8″ ER11 High Precision Collet

Ultimate Bundle

Add the Ultimate Bundle to maximise productivity and start using your WorkBee to grow your income.

Mafell FM 1000 Router Head

43mm WorkBee Router Mount

WorkBee XYZ Touch Probe

Dust Shoe

General Purpose Starter Router Bit Kit

1-1/8″ Amana Tool 45525 Surfacing Router Bit (1/4″ Shank)

1/4″ Mafell FM 1000 Collet

1/8″ Mafell FM 1000 Collet

MATERIALS GALORE!

With a WorkBee CNC Machine you can cut a huge range of materials including:

- Foams

- Plastics

- Woods

- Carbon Fibre

- Aluminium

- Everything inbetween

Materials can be cut 44mm the whole way through.

DESIGNED & MADE IN BRITAIN

The WorkBee Z1+ is designed and manufactured at our site in the southeast of the UK, we employ a team of local people who carefully produce and package each CNC Machine.

THE WORKBEE IS FOR YOU IF…

- You want to add personalised products to your range.

- You want to turn ideas into sellable products.

- You want to automate parts of your workflow

- You want to increase output without working more hours.

- You want a machine that pays for itself quickly.

- You want to earn more profit from every job.

UK BASED CUSTOMER SUPPORT

We pride ourselves on our customer service, our expert team is available to answer any queries you may have!

We understand using a CNC Machine can be new to many, but we are here to help.

4′ x 4′ SHEETS – NO PROBLEM

The WorkBee Z1+ comes in a range of sizes – the biggest CNC Machine can cut 4′ x 4′ without a sweat!

For full 8′ x 4′ sheets use CAM Software tiling functions.

Insanely accurate. . . ± 0.1mm is achievable on all sizes of the WorkBee Z1+ CNC Machine with it’s lead screw drive system.

With this level of accuracy, even PCBs can be manufactured on the WorkBee CNC Machine.

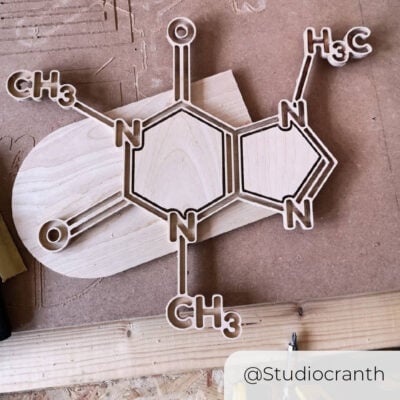

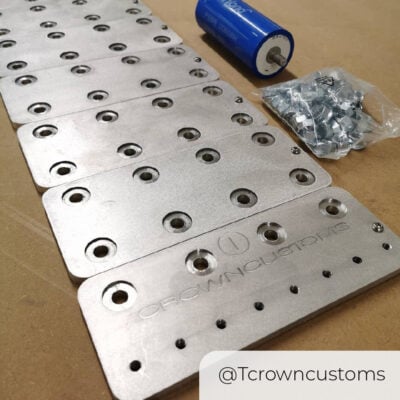

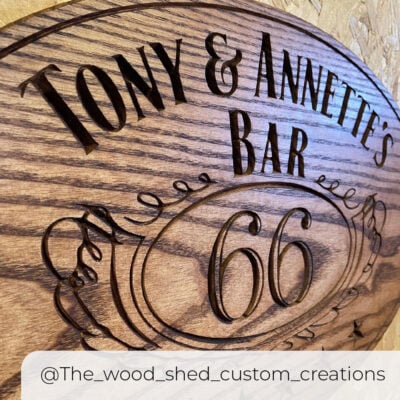

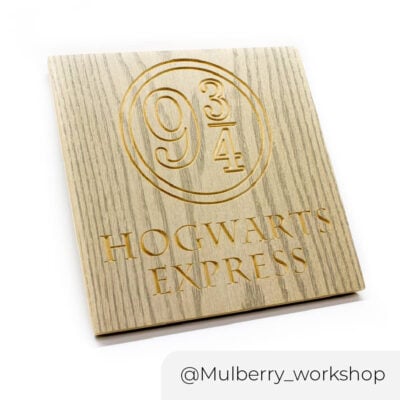

COMMUNITY SHOWCASE

A WORKSHOP COMPANION

Having a WorkBee CNC Machine is like have an extra set of hands – it is an investment to supercharge your business.

Let the WorkBee Z1+ help you manufacture your products again and again.

A CNC Machine can free your time to develop ideas, create more products and ultimately grow your business.

CONFIGURE YOURSA WORKSHOP COMPANION

Having a WorkBee CNC Machine is like have an extra set of hands – it is an investment to supercharge your business.

Let the WorkBee Z1+ help you manufacture your products again and again.

A CNC Machine can free your time to develop ideas, create more products and ultimately grow your business.

CONFIGURE YOURS

AN EDUCATIONAL TOOL

The WorkBee is also ideal for educational & research settings. You will find a WorkBee CNC Machine already in many Schools, Universities and Makerspaces around the world, such as Manchester and Oxford University – so why not get one in your classroom too!

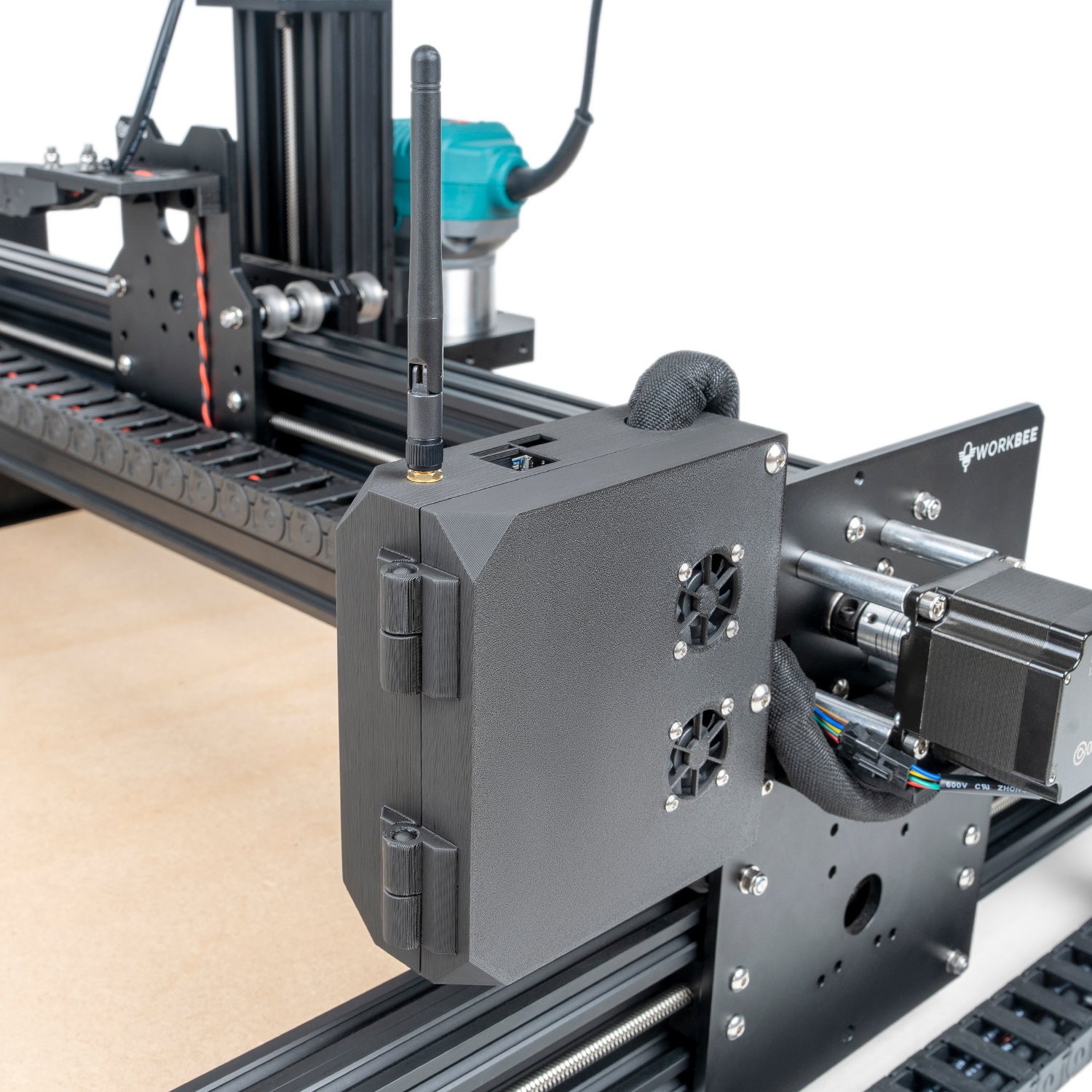

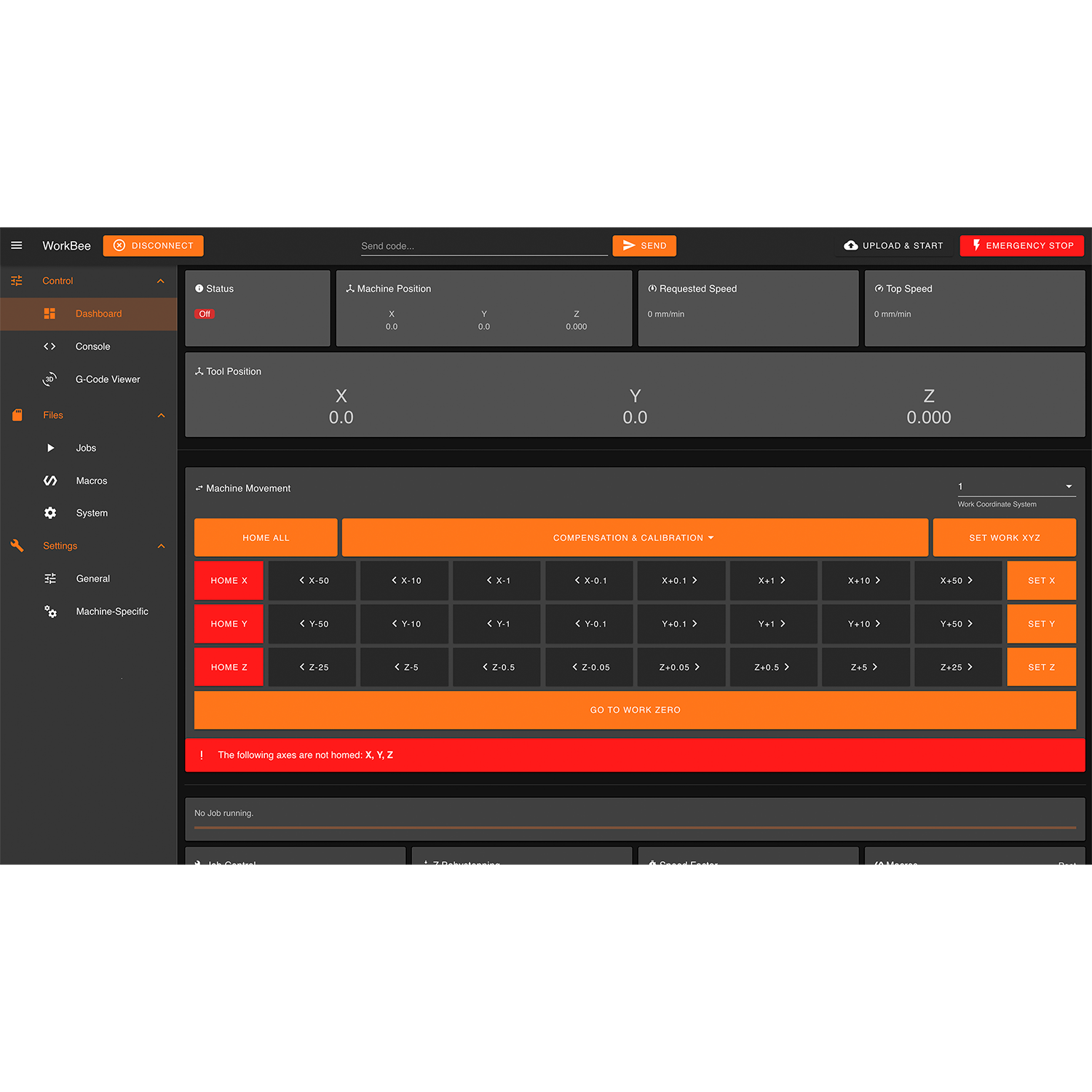

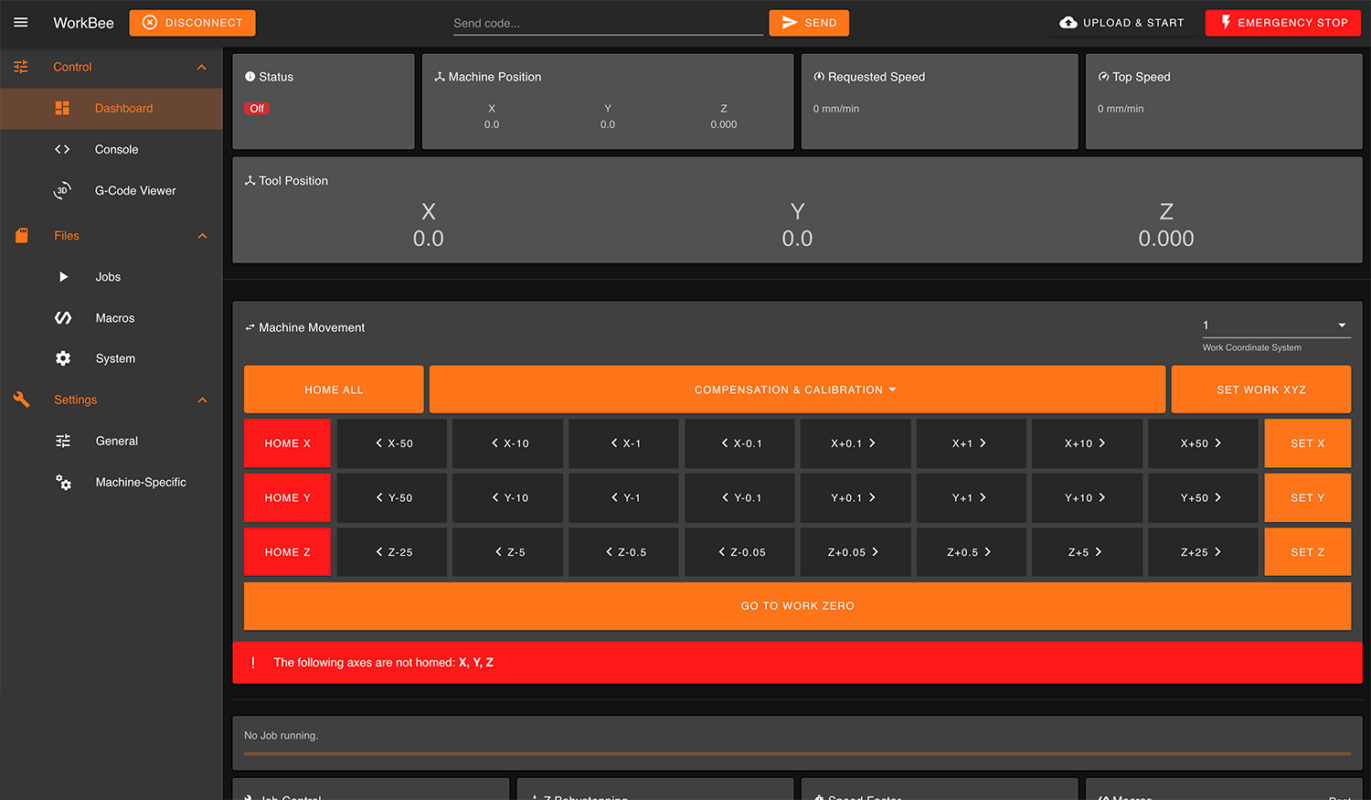

CAD > CAM > WORKBEE CONTROL

1. Use CAD/CAM Software to design your ideas and generate toolpaths (G-Code). Carveco, Vectric and many more favourite CAM Softwares can be used.

2. Use your computer, tablet or phone web browser to open the built-in WorkBee Control interface via Wifi. Ethernet version also available*.

3. Send created toolpaths to your CNC Machine using WorkBee Control.

*Ethernet cable is connected directly from machine to computer and does not require internet.

WHAT OTHERS SAY

” The customer service is amazing giving a very personal feel to the process… Without Ooznest I don’t think I would be enjoying the WorkBee CNC Machine as much as I am. “By Miss Laugharne

” This company definitely suited to the absolute beginner… I’d read the after sales support was excellent, they lived up to it.

Only praise!! “By Christopher Green

” …my WorkBee CNC Machine experience has been great and the machine’s been reliable despite my efforts to break it… I can’t give 6 stars despite the team being worthy of more… “By Dave / Daveworxwood

” The customer service is amazing giving a very personal feel to the process… Without Ooznest I don’t think I would be enjoying the WorkBee as much as I am. “

By Miss Laugharne

” This company definitely suited to the absolute beginner… I’d read the after sales support was excellent, they lived up to it.

Only praise!! “

By Christopher Green

” …my Workbee experience has been great and the machine’s been reliable despite my efforts to break it… I can’t give 6 stars despite the team being worthy of more… “

By Dave / Daveworxwood

Reviews collected on Trustpilot

LEARN HOW TO BUILD A CNC MACHINE

The WorkBee Z1+ is a self build CNC Machine Kit, and our easy-to-follow and detailed assembly manuals make the build almost as fun as using the machine!

Building your own CNC Machine yourself will equip you with knowledge of all the ins and outs of the machine – making maintenance much easier.

Only simple tools are required (spanners, allen keys, screwdrivers etc.) – all the crimping, soldering, and commissioning the controller are all done for you!

VIEW THE MANUALSLEARN HOW TO BUILD A CNC MACHINE

The WorkBee Z1+ is a self build CNC Machine Kit, and our easy-to-follow and detailed assembly manuals make the build almost as fun as using the machine!

Building your own WorkBee yourself will equip you with knowledge of all the ins and outs of the machine – making maintenance much easier.

Only simple tools are required (spanners, allen keys, screwdrivers etc.) – all the crimping, soldering, and commissioning the controller are all done for you!

VIEW THE MANUALSWHAT'S INCLUDED

INCLUDED WITH EVERY WORKBEE Z1+

Mechanical Frame

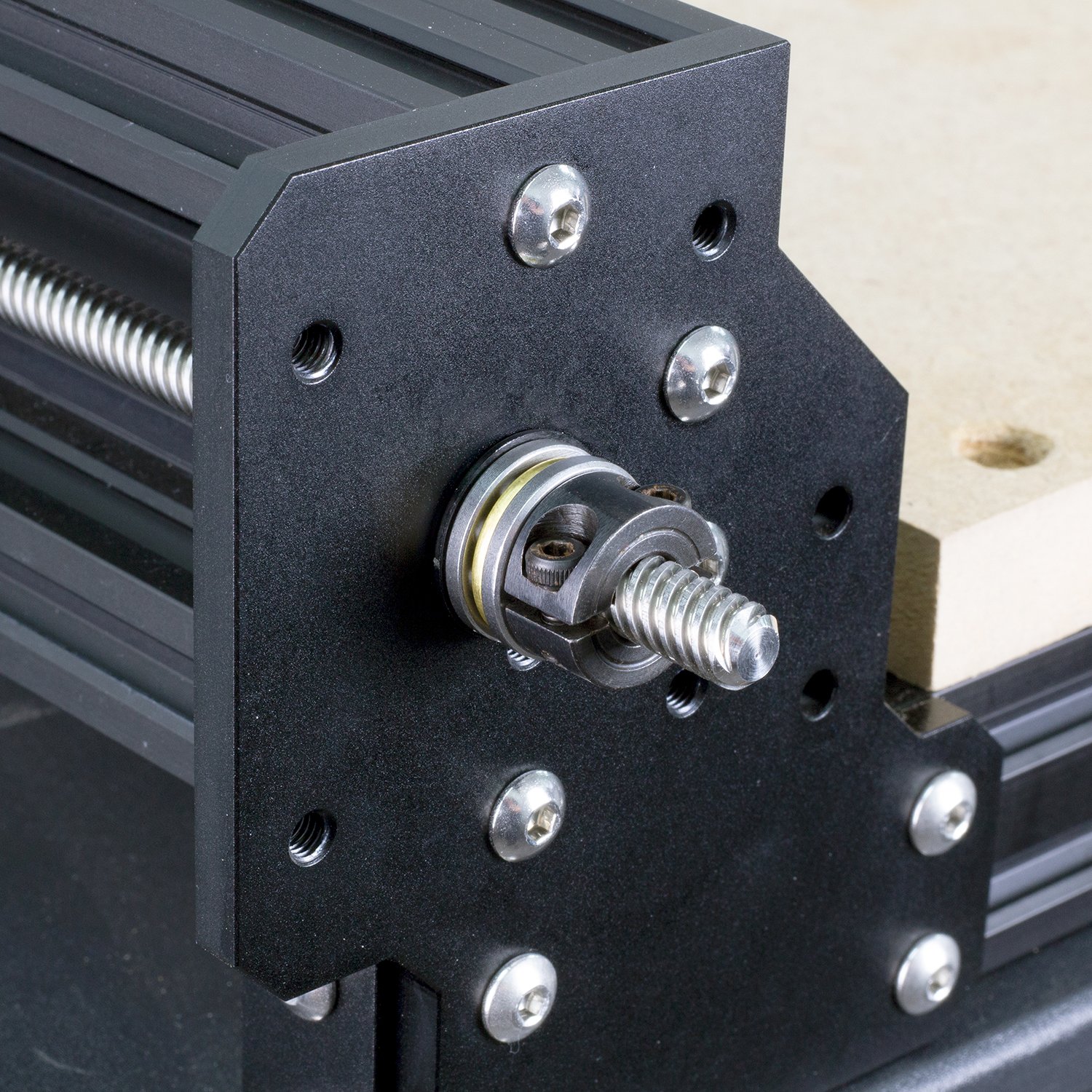

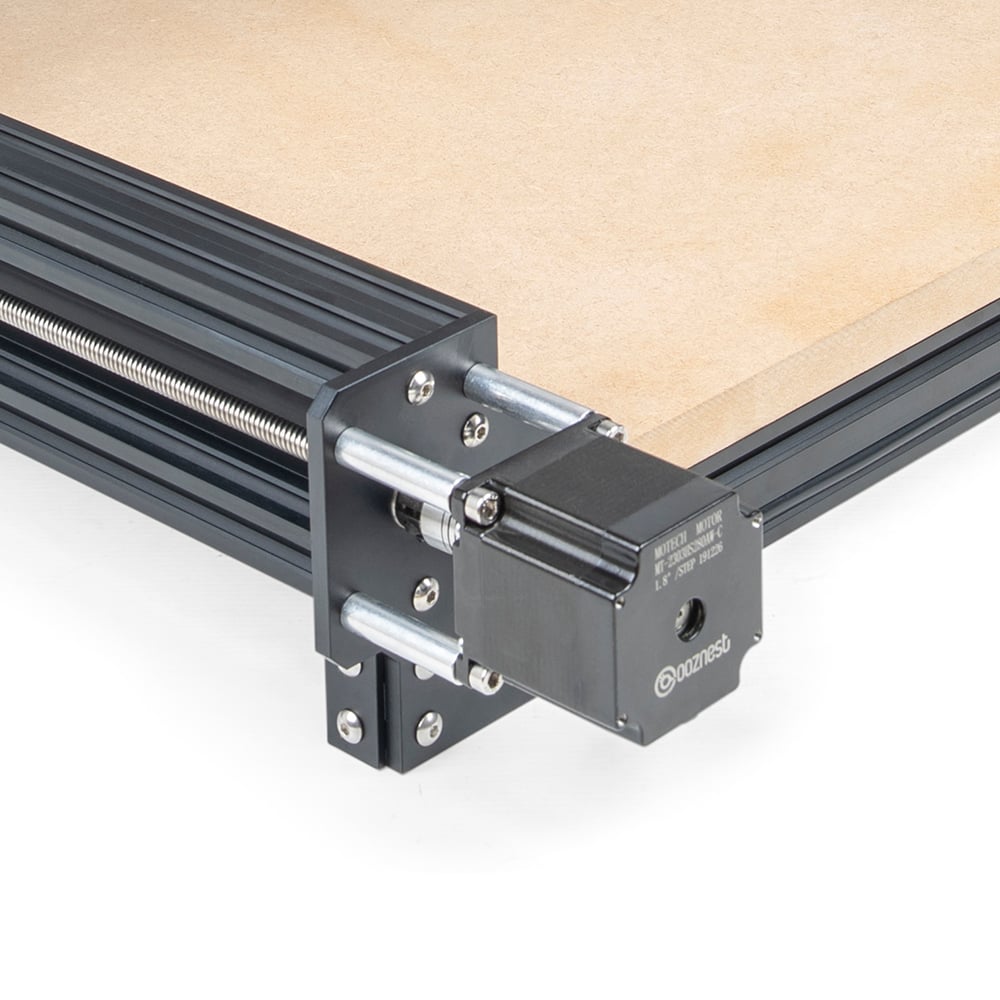

Lead Screw System

Wheel Motion System

+ Wheel Adjustment Spanner

Drag Chains

Router Mount

Stepper Motors + Wires

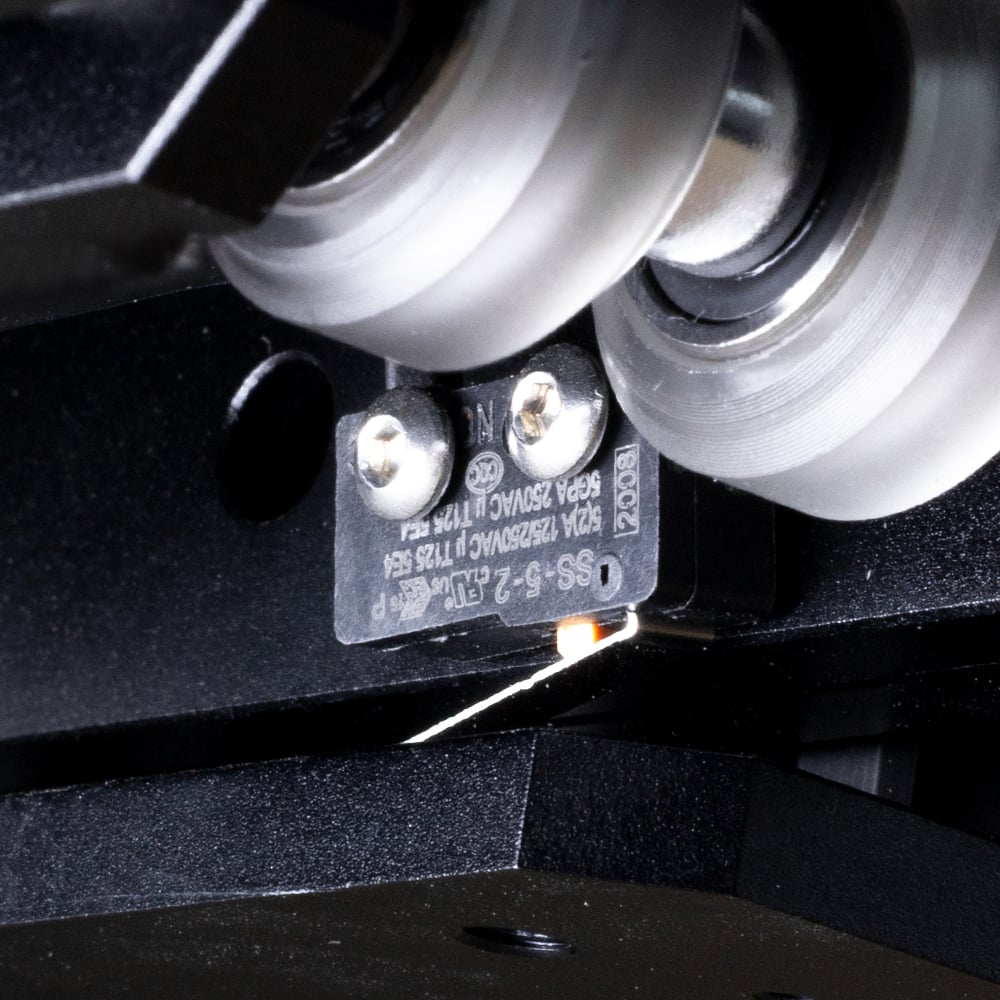

Limit Switches

Controller & Case

Power Supply + Emergency Stop

WorkBee Control

1/4" End mill

+ 30° Calibration End mill

Treats

WHAT YOU CAN ADD AS EXTRAS

* REQUIRED TO OPERATE THE WORKBEE Z1+ AS A CNC MACHINE.

* RECOMMENDED TO GET THE MOST OUT OF YOUR WORKBEE Z1+

Router Head

Endmill Kit

Dust Shoe

CAM Software

Touch Probe

Enclosure

Surfacing Bit

THINGS WE DON'T SUPPLY THAT YOU WILL NEED

MDF Spoilerboard*

Cut to size from a builders merchant (B&Q / Home Depot)

Workpiece Clamps

Recommended UJK System from Axminster

Extraction System**

Recommended from Axminster

(Intended Runtime Dependant)

*Required dimensions can be found on Technical Tab

**An extraction system is only required if the Dust Shoe is chosen in the configurator

FAQs

Check out these FAQs for answers to the most common questions you might ask before purchasing your WorkBee Z1+!

If you cannot find the answer you are looking for, find us on Live Chat, Whatsapp or fill in a Contact Form and our expert team will be happy to help.

You can also book a call-back with our sales team - use the Contact Form to request one.

The WorkBee Z1+ is a CNC router machine that can cut, carve and engrave a wide variety of materials.

It is a very versatile machine and can be used for many different projects and applications.

As well as cutting and carving endless things, it can also be applied in different scenarios like rapid prototyping, marking out plot points, drawing and research projects etc.

With a WorkBee Z1+ you can make and manufacture an endless list of things!

Its ability to cut, carve and engrave with ease, means you can pretty much make anything you can imagine in your own workshop.

Some examples include:

- Signs

- Toys

- Gifts

- Furniture

- Engineering parts

- Fixtures/Jigs

- Guitars

- Home decorations

- Kitchen accessories

and the list goes on. . .

Check out our Instagram to see what other WorkBee owners have been creating!

If you are an absolute beginner to CNC Machining, the learning curve really depends on how competent you are with a computer. If you have used any type of computer design programs before, then learning the programs that operate a CNC Machine should be fairly easy.

If you haven't got much experience with a computer and have not really used design programs before then it will be a learning curve, but a good one!

If you are a beginner we would recommend buying the software we offer with the machine. Either Vectric Cut2D, VCarve or Carveco Maker. From our experience, these are the easiest programs to use but are still very powerful.

Both programs have beginner tutorials projects to get you started:

Vectric - The Basics

Carveco - Tutorial Projects

We have a guide on running your first project on the WorkBee - First Project

In addition, the Vectric & Carveco software is what we mainly use at Ooznest, so therefore we can provide the best support possible.

The machine comes in kit format, building the machine should be very easy as long as you follow our online guides on our learning portal: https://learn.ooznest.co.uk/

Yes. The WorkBee Z1+ is an ideal machine for your business.

You can use the WorkBee as a production tool to actually manufacture or prototype your products.

Or you can use it to make fixtures, jigs, and devices that expedite the assembly or production of other projects.

A WorkBee Z1+ can help you save time while ensuring accuracy in the work.

It can also increase production on repetitive jobs as it can be set up to run the same projects each day with minimal effort, but maximum output.

The WorkBee Z1+ can help you bring essential and bespoke manufacturing back in-house!

Yes, the WorkBee Z1+ makes a great addition to the classroom to allow students to gain skills for a new age of digital computer-aided design and manufacturing – skills for the modern workplace.

We currently supply over 70 schools and Universities in the UK with our WorkBee CNC machines.

The WorkBee Z1+ is a self-build kit that is easy and safe to use - and also makes a great team project.

It can be used for students to both make and create within D&T education as well as learn CNC machine design, electronics, and digital manufacturing.

Yes the Ooznest Original WorkBee Z1+ comes with a 1-year limited warranty. More information can be found here

Check out the What's Included tab for all the details.

The Original WorkBee Z1+ CNC Machine includes everything you need to build a moving CNC Machine.

The Configurator lists all the extras we offer.

The essential extras you need are: Router Head and CAM Software.

End Mills, Dust Shoe, Touch Probe, Surfacing Bit and Enclosure are all optional extras.

Items we do not supply are the MDF Spoilerboard and Workpiece clamps.

If you buy the Dust Shoe, you will also need a suitable extraction system.

The connectivity is how you will connect to the WorkBee Z1+.

If you will have a strong Wifi signal near the machine – Choose the Wifi version.

If there is no Wifi or the signal is weak – Choose the Ethernet version*.

If you plan to have a computer next to the WorkBee Z1+ at all times - Choose the Ethernet version*.

*The ethernet cable connects directly from the ethernet port on your computer to the WorkBee. No internet is required.

A USB to Ethernet Adaptor can be used - you can get one here.

The Mafell is a purpose-designed milling motor. It is intended for prolonged use.

The Mafell has a noise level of less than 71dB (A). This is significantly quieter than the WorkBee Router Head.

If you are going to use the machine for prolonged use - Choose the Mafell FM 1000

If noise is going to be a concern - Choose the Mafell FM 1000

If none of the above applies - Choose the WorkBee Router Head

The WorkBee has the following software workflow: CAD > CAM > WorkBee Control.

CAD/CAM

The CAD program creates designs and the CAM program turns designs into toolpaths (G-code).

Most CAM programs have basic CAD functionality built-in.

We offer Carveco and Vectric branded software which has great functionality and ease of use. CAM Software can be added in the product configurator.

WorkBee Control

The WorkBee Control software comes built-in on the machine.

It is browser-based so can be used on your computer, tablet* or phone*.

Use WorkBee Control to send the toolpaths to the WorkBee, set work zero and move the machine around.

*tablet/phone functionality only available on the Wifi version of the WorkBee Z1+

The control software, WorkBee Control, is browser-based. Therefore the system requirements are very low, if your computer can run Google Chrome, it can run WorkBee Control.

The CAM Software will require a computer. If using Vectric software the minimum system requirements can be found here:

https://www.vectric.com/support/system-requirements

If using Carveco Maker the minimum system requirements can be found here:

Due to the production line nature of how we make our Ooznest Original WorkBees, we cannot offer any custom sizes outside the standard sizes you see on our Configurator.

The largest WorkBee (1500x1500mm) can cut 4′ x 4′ sheets.

| Machine Size (X x Y) | Working Area (X x Y) |

| 500 x 500mm | 300 x 270mm |

| 750 x 750mm | 550 x 520mm |

| 750 x 1000mm | 550 x 770mm |

| 1000 x 1000mm | 800 x 770mm |

| 1000 x 1500mm | 800 x 1270mm |

| 1500 x 1500mm | 1300 x 1270mm |

The biggest sheet the WorkBee can cut is 4' x 4' sheets. For larger sheets, such as 8' x 4', you can use tiling.

This involves cutting one half of the sheet, pushing the material through, and then cutting the second half.

We have a YouTube video that explains the process: https://www.youtube.com/watch?v=JKyiKZrLPqA

With the recommended 18mm spoilerboard the maximum depth of material you can cut the whole way through is 44mm.

You can cut thicker material up to a maximum of 88mm, but not the whole way through.

With a WorkBee Z1+ you can cut a huge range of materials including:

- Foams

- Plastics

- Woods

- Carbon Fibre

- Aluminium

For a more detailed list please check out the Technical Tab on the product page

If you have a material not listed, get in touch and we can advise.

An impressive ± 0.1mm accuracy is achievable on all sizes of the WorkBee Z1+.

In normal operation, the machine will have a decibel level of ~70-100db.

This will be dependant on the material you are cutting, Router Head, RPM used and type of cut made.

With one of our WorkBee Enclosures you would expect a decibel reduction of ~20db if you use 6mm Perspex panels.

If you used a material like MDF as a panel material, you could expect further noise reductions.

The WorkBee has easy-to-follow and detailed manuals which make the assembly a straightforward and enjoyable activity.

We usually say it will take around 12 hours to build completely.

Only simple tools are required (spanners, allen keys, screwdrivers etc.) - all the crimping, soldering, and commissioning the controller are all done for you!

We're afraid we do not offer an assembly service.

The WorkBee Z1+ is a self build CNC Machine Kit, and our easy-to-follow and detailed assembly manuals make the build almost as fun as using the machine!

The guides on assembling the WorkBee Z1+ can be found on our learning portal: https://learn.ooznest.co.uk/

Building your own WorkBee yourself will equip you with knowledge of all the ins and outs of the machine – making maintenance much easier.

Only simple tools are required (spanners, allen keys, screwdrivers etc.) – all the crimping, soldering, and commissioning the controller are all done for you!

The technical support team are always able to offer assembly help and advice.

We would recommend purchasing a dedicated kit of tools for both the assembly and maintenance of your WorkBee CNC Machine.

You will need the following tools:

|

|

|

It is not recommended to use Power Tools such as Impact Drivers or Drills for the assembly of the WorkBee CNC Machine.

Our instruction manuals cover assembling the machine and cutting your first project. Full training is not something we offer.

However, there are some great resources available online. A few stand-out ones are:

Instruction Manuals: https://learn.ooznest.co.uk/

Ooznest YouTube: https://www.youtube.com/ooznest

Ooznest Instagram: https://www.instagram.com/ooznest

Vectric YouTube: https://www.youtube.com/channel/UCqkhkxqPPLdtYy8ybykTlzQ

Vectric Training: https://www.vectric.com/support/tutorials/vcarve-pro

Carveco Training: https://learn.carveco.com/

CNC Cookbook: https://www.cnccookbook.com/cnc-resources/

Fusion360 YouTube Creator: https://www.youtube.com/channel/UCo29kn3d9ziFUZGZ50VKvWA

We are also available to help along your journey!

Yes, you can arrange a call-back with one of our team to get all your burning questions answered!

Please get in contact to request a call-back.

TECHNICAL

DIMENSIONS

| Machine Size (X x Y) | Working Area (X x Y) | Recommended Spoilerboard Size (X x Y) | Recommended Workbench Size (X x Y) | Weight |

| 500 x 500mm | 270 x 270mm | 360 x 500 x 18mm | 700 x 700mm (800 x 710mm with Enclosure) | 24.8kg |

| 750 x 750mm | 520 x 520mm | 610 x 750 x 18mm | 950 x 950mm (1050 x 960mm with Enclosure) | 28.5kg |

| 750 x 1000mm | 520 x 770mm | 610 x 1000 x 18mm | 950 x 1200mm (1050 x 1210mm with Enclosure) | 30.9kg |

| 1000 x 1000mm | 770 x 770mm | 860 x 1000 x 18mm | 1200 x 1200mm (1300 x 1210mm with Enclosure) | 32.6kg |

| 1000 x 1500mm | 770 x 1270mm | 860 x 1500 x 18mm | 1200 x 1700mm | 37.8kg |

| 1500 x 1500mm | 1270 x 1270mm | 1360 x 1500 x 18mm | 1700 x 1700mm | 40.4kg |

*Weights calculated without a router head, spoilerboard and other additional extras.

| Overall Height | Maximum Cut Depth* | Maximum Z-Axis Travel** |

| 510mm (630mm with Enclosure) | 44mm | 88mm |

*Calculated with an 18mm spoilerboard. Deeper materials can be cut, but you will not be able to cut the whole way through.

**Calculated with an 18mm spoilerboard. Maximum travel if there were no obstructions from a spoilerboard or workbench is 125mm.

CUTTABLE MATERIALS

| Woods | |||||||

| Ash | Balsa Wood | Beech | Birch | Birch Plywood | Cedar | Cherry | Chestnut |

| Chipboard | Cork | Ebony | Elm | Iroko | Laminate | Lime | Mahogany |

| Maple | MDF | Melamine | Oak | Olivewood | OSB | Pine | Plywood |

| Poplar | Rose | Sapele | Spruce | Sycamore | Teak | Tulip | Valchromat |

| Walnut | Wenge | Zebrano | Ziricote | ||||

| Foams | |||||||

| Closed Cell Polyethylene | Open Cell Polyethylene | Expanded Polypropylene | Expanded Polystyrene | Foamboard | |||

| Foamex | High Density Polyurethane | Medium Density Polyurethane | High Density Urethane | Styrofoam | |||

| Plastics | |||||||

| ABS | Acetal | Cast Acrylic | Extruded Acrylic | Corian | |||

| Coroplast | Correx | Delrin | Dibond | High Density Polyethylene (HDPE) | |||

| Low Density Polyethylene (LDPE) | High Impact Polystyrene (HIPS) | Polyether Ether Ketone (PEEK) | Perspex | Polycarbonate | |||

| Polyethylene Terephthalate (PET) | Polymethyl Methacrylate (PMMA) | Polyoxymethylene (POM) | Polypropylene (PP) | Polyvinyl Chloride (PVC) | |||

| Metals | |||||||

| Aluminium* | Brass | Bronze | Copper | Gold | |||

| Lead | Silver | Tin | Zinc | ||||

*Machinable Grades Only including 1100, 2011, 3003 and 6061.

| Other | |||||||

| Rubber | Carbon Fibre | Leather | Wax | PCB | |||

MECHANICAL FRAME

| Extrusions | Plates | Nuts & Bolts |

| Black/Clear Anodised Aluminium Extrusion | 6mm Anodised Aluminium Plates | A2 Stainless Steel |

Motion System

| System | Number of Wheels | Material |

| Wheels on V-Slot Extrusion | 30 | Polycarbonate |

DRIVE SYSTEM

| System | Diameter | Material | Stepper Motors | Maximum Torque | Maximum Feedrate | Accuracy |

| Lead Screw X,Y & Z | 8mm | Stainless Steel | NEMA23 X, Y & Z | 175oz-in | 2500mm/min | ± 0.1mm |

The mechanical resolution is 0.0025mm X/Y-Axis & Z-Axis

The displayed resolution is 0.1mm X/Y-Axis 0.001mm Z-Axis

power

| Input Voltage | Input Current | Frequency | Input Power | Output Voltage | Output Current | Output Power |

| 100-240V | 3.85/1.6A | 60/50Hz | 385W | 24V | 13.34A | 320W |

Power supply is provided with either a UK/EU or US plug as chosen in the configurator.

See 'Routers' section below, for their power requirements.

ELECTRONICS

| Controller | Firmware | Connection | Wifi Channel | Drivers | Number of Drivers | File Storage | Storage Capacity | Precommissioned | Min/Max Temp °C |

| Duet 2 | RepRapFirmware | Wifi or Ethernet* | 2.4GHz Only | TMC2660 - 2.4A | 5 (1 Spare) | Onboard SD Card | 4GB | Yes | 2/55 |

*The Duet 2 board comes as either a WiFi or Ethernet version. To change from one connection method to another will require the purchase of the other version Duet 2.

CONTROL SOFTWARE

| Name | Platform | Installation | System Requirements - Wifi | System Requirements - Ethernet |

| WorkBee Control | Web Browser (Google Chrome Recommended) | Pre-installed on Controller | Any device with a Web Browser | Mac / Windows* |

*Native ethernet port not required. USB to Ethernet adaptor can be used. Do not use a Power over Ethernet adaptor.

Routers

| Model | Input Power | RPM (No Load) | Speed Control | Collets | Noise Level | Plug Availability | Voltage | Weight | Warranty Duration | Warranty Provider |

| WorkBee Router Head | 710W | 13000 - 33000 | Manual | 1/4" (6.35mm) & 1/8" (3.175mm) | 95dB (A) | UK | 230V 50Hz | 1.51kg | 1 Year (Excluding Brushes) | Ooznest |

| Mafell FM 1000 Milling Motor | 1000W | 4000 - 25000 (UK / EU) 10000 - 25000 (US) |

Manual | 1/4" (6.35mm) & 8mm | 71dB (A) | UK / EU / US | 110/230V 60/50Hz | 1.65kg | 1 Year (Excluding Brushes) | Mafell |

ENDMILLS

| Included With Every WorkBee Z1+; | ||||||

| Type | Cut Ø | Shank Ø | Flutes | Cut Length | Overall Length | Material |

| Square End | 1/4" (6.35mm) | 1/4" (6.35mm) | 2 - Up-Cut | 1/2" (12.7mm) | 5/2" (63.5mm) | Solid Carbide |

| Optional Endmill Kit | |||||||

| Type | Cut Ø | Shank Ø | Flutes | Cut Length | Overall Length | Material | Angle |

| Square End | 1/4" (6.35mm) | 1/4" (6.35mm) | 2 - Up-Cut | 1/2" (12.7mm) | 5/2" (63.5mm) | Solid Carbide | |

| Square End | 1/8" (3.175mm) | 1/8" (3.175mm) | 2 - Up-Cut | 3/8" (9.525mm) | 3/2" (38.1mm) | Solid Carbide | |

| Square End | 1/16" (1.5875mm) | 1/8" (3.175mm) | 2 - Up-Cut | 47/250" (4.7752mm) | 2" (50.8mm) | Solid Carbide | |

| Ball End | 1/4" (6.35mm) | 1/4" (6.35mm) | 2 - Up-Cut | 3/4" (19.05mm) | 5/2" (63.5mm) | Solid Carbide | |

| Ball End | 1/8" (3.175mm) | 1/8" (3.175mm) | 2 - Up-Cut | 3/8" (9.525mm) | 3/2" (38.1mm) | Solid Carbide | |

| Ball End | 1/16" (1.5875mm) | 1/8" (3.175mm) | 2 - Up-Cut | 47/250" (4.7752mm) | 2" (50.8mm) | Solid Carbide | |

| Engraver | 1/20" (1.27mm) | 1/8" (3.175mm) | 3/2" (38.1mm) | Solid Carbide | 90° | ||

| If the Mafell Router head is chosen, a 1/8" (3.175mm) collet is also included for your chosen Router. | |||||||

| Optional Surfacing Bit | ||||||

| Type | Cut Ø | Shank Ø | Flutes | Cut Length | Overall Length | Material |

| Square End | 1-1/8" (28.575mm) | 1/4" (6.35mm) | 3 - Straight | 1/2" (12.7mm) | 1-13/16" (46.0375mm) | Carbide Tipped |

Dust shoe

| Shoe Attachment | Brush Attachment | Brush Length | Outlet Ø |

| Clamping | Magnetic | 2" (50.8mm) | 2-1/2" (63.5mm) |

Touch Probe

| Detachable | Material | Size | Corner Probe | Z Probe | Maximum Endmill Ø | Software Control Panel |

| Yes | Aluminium | 60x60x10mm | Yes | Yes | 8mm | Yes |

DELIVERY SIZES AND WEIGHTS

| Machine Size (X x Y) | Box 1 - Size & Weight | Box 2 - Size & Weight |

| 500 x 500mm | 457 x 457 x 305mm @ 15.2kg | 1200 x 300 x 300mm @ 9.6kg |

| 750 x 750mm | 457 x 457 x 305mm @ 15.4kg | 1200 x 300 x 300mm @ 13.1kg |

| 750 x 1000mm | 457 x 457 x 305mm @ 15.5kg | 1200 x 300 x 300mm @ 15.4kg |

| 1000 x 1000mm | 457 x 457 x 305mm @ 15.7kg | 1200 x 300 x 300mm @ 16.9kg |

| 1000 x 1500mm | 457 x 457 x 305mm @ 15.9kg | 1600 x 300 x 300mm @ 21.9kg |

| 1500 x 1500mm | 457 x 457 x 305mm @ 16.1kg | 1600 x 300 x 300mm @ 24.3kg |

Number of boxes, sizes, and weights may change depending on selections in the configurator and other items bought elsewhere on the website.

DELIVERY

WorkBees are usually despatched in 1-3 working days after you have placed the order. Delivery aims given are from despatch date.

For full information about WorkBee Delivery, please read the main Delivery Information page

UK MAINLAND WORKBEE DELIVERY

|

Courier service |

Delivery Aim |

Tracked |

Price |

|

APC |

1 working day |

Fully |

Free |

NON-MAINLAND UK / RESTRICTED UK LOCATIONS (see ‘Delivery Service Restrictions’ table here)

|

Courier service |

Delivery Aim |

Tracked |

Price |

|

APC |

1-5 working days (depending on location) |

Fully |

Add items to your basket. Press ‘Calculate shipping’ and enter your address and press ‘update’. |

INTERNATIONAL WORKBEE DELIVERY

|

Courier service |

Delivery Aim |

Tracked |

Price |

|

DHL Express* |

1-2 working days |

Fully |

Add items to your basket. Press ‘Calculate shipping’ and enter your address and press ‘update’. |

|

DHL Express Taxes & Duties paid** |

1-2 working days |

Fully |

Add items to your basket. Press ‘Calculate shipping’ and enter your address and press ‘update’. |

|

DHL Economy* |

2-5 working days |

Partially |

Add items to your basket. Press ‘Calculate shipping’ and enter your address and press ‘update’. |

|

DHL Economy Taxes & Duties paid** |

2-5 working days |

Partially |

Add items to your basket. Press ‘Calculate shipping’ and enter your address and press ‘update’. |

Please note not all services are available to every location.

* These delivery service options only cover cost of Delivery. You will pay Ex VAT prices on our website. Import Taxes/VAT, Import Duties, and Custom clearance fees will be invoiced directly from the courier to you.

Due to the Trade and Cooperation Agreement (TCA) between the UK and EU, no customs duties should be applied on orders shipped to the EU from UK origin.

** These delivery service options cover Delivery costs, Import Taxes/VAT, Import Duties (if applicable) and custom clearance fee. Import VAT invoices cannot be provided.

DELIVERY SIZES AND WEIGHTS

| Machine Size (X x Y) | Box 1 - Size & Weight | Box 2 - Size & Weight |

| 500 x 500mm | 457 x 457 x 305mm @ 15.2kg | 1200 x 300 x 300mm @ 9.6kg |

| 750 x 750mm | 457 x 457 x 305mm @ 15.4kg | 1200 x 300 x 300mm @ 13.1kg |

| 750 x 1000mm | 457 x 457 x 305mm @ 15.5kg | 1200 x 300 x 300mm @ 15.4kg |

| 1000 x 1000mm | 457 x 457 x 305mm @ 15.7kg | 1200 x 300 x 300mm @ 16.9kg |

| 1000 x 1500mm | 457 x 457 x 305mm @ 15.9kg | 1600 x 300 x 300mm @ 21.9kg |

| 1500 x 1500mm | 457 x 457 x 305mm @ 16.1kg | 1600 x 300 x 300mm @ 24.3kg |

Number of boxes, sizes, and weights may change depending on selections in the configurator and other items bought elsewhere on the website.

142 reviews for Original WorkBee Z1+ CNC Machine

Only logged in customers who have purchased this product may leave a review.

Andrew Barnard (verified owner) –

unfortunately i have had the chance to use it properly yet, but i cant say enough about the customer service it was very good, if the router is half as good i will be happy.

Mark Evans (verified owner) –

Awesome piece of kit. Strong, smooth and precise. Very well documented build, easy to follow.

Buglet (verified owner) –

Looks very well made. Setup instructions very clear but quite time-consuming – a (fun) project in itself!. Run test project and it works well after detailed setup. See my overall review of the machine.

Ian Beardmore (verified owner) –

Great machine , great improvements , much easier to use , accuracy is brilliant , very pleased A**

Paul Richards (verified owner) –

I’m right at the start of a steep old learning curve. I was very impressed with the instructions and build procedure. It’s lengthy but quite enjoyable. Ooznest have provided class leading support where needed. I am 100% happy with the product.

Bachrach (verified owner) –

good value for money but rigidity leaves to be desired.

this really is a hobby grade machine, don’t get you hopes up for aluminium routing and fast production

Christian C (verified owner) –

I love this machine. I still feel I haven’t yet reached its true potential, and I am getting great results

Fred (verified owner) –

bon produit

Gav Willoughby (verified owner) –

This unit is a breast. For a small home unit, I cannot fault it.

Advice for anyone buying one, go for every option, and get the largest size you can fit into the space.

Aidan Letzer (verified owner) –

My first cnc, brilliant fun to build, easy instructions to follow. High degree of accuracy as well as being powerful enough to plough through material like it’s not there.

Client (verified owner) –

The best kit on the market, by far

Silvan (verified owner) –

overall a nice product

Adam Twigger (verified owner) –

Beast of a machine, considering its a desktop entry level.

benito dumont (verified owner) –

Everything is perfect

jft (verified owner) –

Very good quality, good value for money

Kevin Harris (verified owner) –

Great price for the price. Customer service is amazing and I would highly recommend them to anyone

Bj√∏rn (verified owner) –

Very good manuals to build the CNC-machine and rapid freight to Norway.

roy cruse (verified owner) –

Only time will tell if this good value CNC keeps up with the jobs I send to it

Andy (verified owner) –

Love mine, if you are on fence about getting one then just get it, you won’t be disappointed

Donie (verified owner) –

Instructions are good to build the machine but instructions to make a proper spoiler oars are left to YouTubers who don’t do a great job of it. Would be nice to have clearer instructions for this stage.

Oozenest videos are poor. You’re kinda left on your own once it’s built.

I bought the mill set and they are imperial and would be nice if metic and instructions for say Carve or Fusion 360 to set up those tools.

Overall good, but lacking in follow through.

Dan Johnson (verified owner) –

It a good machine for the price. I’m glade I go it. can’t wait to learn more and start doing projects.

UK traveller (verified owner) –

It took me several years of reviewing machines on the market but at the end of the day it’s been worth waiting for. It cost me more than initially planned but now fully built and operational, why did I wait.

James (verified owner) –

It’s a good quality product and hopefully once it gets a little more familiar to me I will enjoy using it . Think some little improvement s could be made . Control box a little small . Instructions were not 100% clear to myself but I’ve never built anything this technical before . Think a little more consideration could be made for your average wood person who hasn’t the best computer knowledge could be made. I’ve mostly enjoyed the build but found something’s a little difficult and a little overwhelming. I must confess thou I am not the most mechanical minded or computer kinda person. This has all been a big learning project for myself and very intriguing and full of ups and downs so far. Most of the downs inffact all of them were caused by my stupidity thou. Ooznest is British company and this is the reason I purchased from them and if all goes well with my CNC adventure I will hopefully purchase from them again.

Ray Southwood (verified owner) –

Instructions good, all assembled ok

David Gedney (verified owner) –

Great machine can do some professional work on it and faster than I was expecting

Thomas Hawkins (verified owner) –

This machine is big enough to handle all the projects I need to run. The repeatability and quality of the machine is impressive. Good job Ooznest!

Steve (verified owner) –

Fantastic piece if kit. Really straight forward instructions make it good fun to assemble as well.

Ross Butler (verified owner) –

The instructions for this item really needs updated. I read probably 40 mistakes out of the 200 steps taken to build this model.

You should not buy this item if you have basic engineering skills, you need to be at a moderate level with some CNC experience to ensure you build this safely

Alessandro Camerota (verified owner) –

Very good quality and a manual that explain everything detailed and easy to build together.

John Barlow (verified owner) –

Excellent product – very well packaged and labelled. Comprehensive instructions on line enabled construction and testing to go without problems. Highly recommended

Tom (verified owner) –

Just finished my first ‘Hello world’ project! I was surprised (very positively!) at the quality of the cut, the dimensions precision, and the smooth cutting process – no doubt also testament to detailed build manuals I followed meticulously! Great machine and I am looking forward to my next project where I can use it!

Triyawan Triyawan (verified owner) –

Excellent.

Jim (verified owner) –

Excellent quality

Mr Peter Phillips (verified owner) –

Speaking as a complete novice to cnc, I was a bit daunted by all the kit that turned up. However, as long as you carefully follow the on-line instructions, you’ll be ok. The tips at the end of each section are very useful. The quality of the parts is exceptional and having put the whole thing together everything is working! The only part I struggled with was the routing the cables through the drag chains.

Stephen Dooley (verified owner) –

As a newbie to CNC I am very happy with this machine, which I bought with the Mafell spindle. It is a little daunting building it yourself, but in practice the instructions are comprehensive and easy to follow, and having built it, I now know exactly how it works and is constructed which is a great advantage when maintaining and using it. I have a number of detailed comments which I will relay to Oozenest, but the main issues for me were (1) the routing of the wiring and the construction of the wiring loom where, it seems to me, some minor design change would make installation much easier, and (2) the positioning of the eccentric wheel adjusters on the Y Axis carriage which make it extremely difficult to adjust.

Terence Adams (verified owner) –

Excellent product and post sales support

Philip Davidson (verified owner) –

Excellent build instruction which are enhanced with user comments. The kit is of high quality and feels like it will last a long time

pierre (verified owner) –

Great product. Works very well.

Ian Garry Cullen (verified owner) –

really pleased

James Ambrose (verified owner) –

Pre ordered this unit, so i was one of the first people to get this version.

I had a couple of issues with parts. But it was swiftly and expertly dealt with the excellent customer support team.

Instructions were mostly fantastic. Clear, concise and full of pictures.

Mechanically, a joy to put together.

Electronically, I would personally improve some aspects of the electronics enclosure design. Also a couple of the instructions were slightly incorrect. but other than that, it still all worked well and it was connect together and play.

A great machine to defiantly start CNC machining on 🙂

Steven Clarke (verified owner) –

Received the product with a few damaged parts. Instructions were not the clearest i have ever seen. However, when i contacted customer service, they were really good and even when i had a technical issue, they were really good. But i would recommend the following if ooznest see’s this.

Couple of mods would make this much better.

1. Option of spoiler board to be included

2. A few gcodes on a memory stick or something, surfacing gcode and various grid options.

3. a couple of novelty things to try would also be good, such as a simple bowl or tea light holder.

4. More of a variety of CNC bits included, like chamfer bit, roundover, pencil bit, V bit.

All in all, i am enjoying the machine thus far with what i have managed to achieve.

Peter Honey (verified owner) –

Very good but went down in price just after purchasing, hence 4 stars.

AT (verified owner) –

For this size of machine there is almost no competition on the British mainland.

Alan (verified owner) –

Just a few niggles but overall a great product for the price and good customer aftercare

Dominique L. (verified owner) –

Great machine.

Mr john parry (verified owner) –

Good item easy to build but online manual could be improved, good that buyers put comments in as this helps not doubling up on jobs

Assistance that is given is excellent and helpful, one star down as there is always room for improvement as my boss keeps telling me üòÅ

Thomas Copestake (verified owner) –

Great kit, good instructions, simply love it!

Mr John Wheeler (verified owner) –

I wasted so much time and money buying cheap Chinese parts, I only wish someone told me about Openbuilds product range and Oosnest as the main UK supplier…….You live and Learn!

Mike robertson (verified owner) –

Very well engineered.

Philip Abbott (verified owner) –

Great piece of kit. I’ve used larger industrial machines and had some concerns but so far it’s done everything I’ve asked of it with ease.

Paul (verified owner) –

I am a complete beginner in this field and was keen to explore the possibilities of using a CNC machine to make things. I have just finished building the machine and what a thoroughly enjoyable experience it was coupled with the pride in making my first object even if it did rely heavily on one of the tutorials. I did need to ask Ryan a couple of questions but these were more down to me not following the instructions. The kit is great. This is Lego Technics on steroids. The instructions are great and there is always Ryan when or if you get stuck. The feel good factor is amazing.

Mr Graydon Cock (verified owner) –

Excellent Choice

John Buckle (verified owner) –

I have been very pleased with all aspects of my experience purchasing, receiving, ease if build (great instructions), quality of components and follow-up support from the OozNest team.

Ben Flynn (verified owner) –

I am really pleased with my Workbee 1010.

Enjoyable assembly process and getting to know the mechanics of the machine all helped by clear step-by-step instructions. If needed, customer service are also very helpful and quick to respond.

Tautvydas Dulskis (verified owner) –

Like black design

EAJ (verified owner) –

Working as advertised

Brian Carter (verified owner) –

Good Stuff, enjoyed putting it together too!

JD (verified owner) –

Very well machine. Lots of options. Very pleased with my purchase. Ozone’s have great customer service too.

Phillip holmes (verified owner) –

What an amazing machine build quality is amazing can’t keep out of the garage

Joaquin Figaredo (verified owner) –

Great product

Rob Willis (verified owner) –

Really nice machine, comprehensive online instructions, all bolts and fixings well packaged and marked clearly

Mr L Gormley (verified owner) –

Easy to use software and nice,clear well labelled functions.

Gary Williams (verified owner) –

Great product

Andy Tice (verified owner) –

Very good product

Paul Charlton (verified owner) –

Very happy with my workbee. Thorough and easy to understand instructions, and high quality components made this a pleasure to build.

Bertie Webster (verified owner) –

Oh my gosh, this thing is massive. Just what I wanted. However, having a few technical issues getting the program up and running. Hoping this is a minor fix and a quick fix, cause I am super excited to get started. But the quality of this machine is awesome and strong, especially comparing to others that I have checked on. Love the look also.

Steve Andrews (verified owner) –

I can’t really give a full and honest opinion of this just yet. Being completely new to CNC I opted for a hopefully simpler and cheaper version of the software as a starting point. All seems relatively straight forward, so see how I get on and upgrade as I need. This is one good thing about the Vectric software.

Bob (verified owner) –

Quality, the kit is considered a budget kit, it isn’t a few dollars or pounds, but few hundreds, yet when I received the CNC kit It was very clear that it worth every penny!

You basically receive proper quality parts that are properly organised and packaged.

Philip Sinclair (verified owner) –

Excellent product

Mr David Sanderson (verified owner) –

Build is fun task on it’s own. All went smooth apart from a small mistake by me. Ooznest support team identified problem. After fix all built and running.

John Clothier (verified owner) –

Outstanding product manufactured in the UK. Great value for money especially when you consider the support around it!

Dragan Pavlovic (verified owner) –

I LIKE IT. ENJOY ASSEMBLING

Sami (verified owner) –

So far im very please to quality of the machine

M Stenning (verified owner) –

Having grown up with the invent of technical Lego, this is great to be putting together. Have had to hold back on working through the night to get finished!!

Michael Hottwagner (verified owner) –

Solid quality, so far i did not notice any problem with Katsu/Makita Mount

Richard Orton (verified owner) –

Self build but with very good instructions and all parts well marked. Encountered a couple of problems one my own fault the other software but this was promptly rectified by Ooznest.

Michael Darlow (verified owner) –

First rate software. Intuitive and easy to use with lots of useful tutorials to get you going. Up to now everything I have wanted to do has been straightforward and easy with VCarve Desktop.

James Hilton (verified owner) –

Good build quality, very happy with machine

Prof BP (verified owner) –

Ecellent

Alexander Wardle (verified owner) –

Overall a very good experience. Just a shame they take so long but you can’t rush quality

R. Zeigler (verified owner) –

Great workmanship

simon whitaker (verified owner) –

Awesome piece of kit

Bach Wood Works (verified owner) –

Its early days for me with this but overall I am totally impressed by the quality of parts and components, the packaging and the documentation provided.

Andrew Peerless (verified owner) –

Awesome product and service

Mark B (verified owner) –

We particularly wanted a machine with screw operation (rather than belt) for increased accuracy. The assembly instructions online were very clear for the step-by-step build process and we have already secured orders where part of the order will run on the machine and cover the initial purchase cost. Thanks Ooznest.

Graphite Signs (verified owner) –

Extremely well made kit, very well packaged and labeled, made building very relaxing and enjoyable. This for the money is a great piece of kit.

Peter (verified owner) –

Steady and well machined

Dave Gooding (verified owner) –

Really pleased with the machine – it was straightforward to assemble by methodically following the clear instructions. All the component parts were clearly packed and marked so there was no ambiguity. Seems to be very high quality, but I’ve not used it much yet.

Andreh Khachatourian (verified owner) –

Worth to have it!

Robert Peissl (verified owner) –

Bin begeistert!

Mr Thomas Mercer (verified owner) –

very good company to deal with will use again

A Mellor (verified owner) –

Excellent bit of kit, great fun putting it together.

Bruno Anastacio (verified owner) –

Great quality piece of machinery, robust and looks nice. Not clunky but also not thin and ‘cheap’ feeling

Marco (verified owner) –

Great entry level CNC. This will work for your hobby needs or till you are ready to spend 10-20k on a professional machine

OLIVIMAGES (verified owner) –

Every part is documented and built from quality materials. You won’t be wrong if investing in the whole package to do good job !

Kristian Falk (verified owner) –

Kan va stabilare.

David (verified owner) –

great and well thought machine. good and robust alu structure and I love the 3D printed plastic parts. it doesn’t always need to be injection molded parts 😉

DR Orest MULKA (verified owner) –

Having read about the kit, I was a bit nervous and expected I would be ringing the helpline. As it happened the build was reasonably straightforward and took 5 afternoons following the online instructions. Connecting to the Duet controller via wifi was a bit hit and miss initially, but I wasn’t using the recommended Chrome browser and I suspect if I had there would have been no problem. The machine worked first time. After using it to drill holes in the wasteboard it started to randomly misbehave. Contact with the helpline was successful in working out that I hadn’t sufficiently tightened the flexible coupling on the z axis and the router assembly was intermittently slipping down. I was impressed by the diagnostics at Ooznest not least because the boss Ryan was giving me advice at 7pm in the evening during the pandemic. An unexpected but welcome benefit of buying British.

The coupling is tricky to tighten because unlike all the other bolts this one is in an eccentric position, so beware.

It works beautifully now

Roberto Boggian (verified owner) –

all parts were available and clearly labelled. With the online instructions the assembly is relatively simple.

Jonathan Pearce (verified owner) –

A fantastic piece of kit.

Mike Newton (verified owner) –

love it, can’t wait for the cnc router to arrive

Craig Knowles – Phoenix Craft Creations (verified owner) –

Love it. Don’t think about it, just get one they’re brilliant. But get the biggest one you can accommodate.

Bjorn Andersson (verified owner) –

I have not yet used the WorkBee very much. Assembly took quite some time, but all parts are very well marked and the instructions are very clear. Everything fit together well and I had no issues building it. Everything seems quality. My biggest complaint is probably that the power supply has holes in it exposing the electronics to dust and particles. It is not suitable for an open CNC router. An IP6x rated power supply would be much better. There is also no proper case for the control board, which is also exposed to dust and particles. However, you can fairly easily 3D print a better case, but I really think a more decent case for the control board should be included.

Overall I’m very satisfied with the product so far, and would absolutely recommend.

oscar d. (verified owner) –

Good quality

mark Mazza (verified owner) –

Great quality parts and hardware

Valentin Berthom√© (verified owner) –

Perfect for me

Paul Dye (verified owner) –

Designed and supplied to match the router I ordered

Robert Landsman (verified owner) –

Pretty well made. There are always thing that one can nitpick, but on the whole a very good setup. I wouldn’t want to build it without the incredible after care help from Ooznest.

Stewart Butcher (verified owner) –

A premium product!

Dave (verified owner) –

Well cut, and brilliantly packed.

Adrian Lawrence (verified owner) –

Great product, a full complete kit.

simon (verified owner) –

Good quality of equipment, detailed instructions, it all worked seamlessly once assembled. Some specific skills are needed to programme up the initial software so the instructions need to be followed to the letter. Very pleased with this purchase which will suit a competent DIY or a small machine shop.

Adrian Brown (verified owner) –

Great Product

Satisfied customer, Staffordshire (verified owner) –

Excellent machine and well designed.

John (verified owner) –

Excellent piece of kit

Scott Morton (verified owner) –

I’m very pleased overall with this purchase for the price I paid and the amount of effort and work put into the whole machine is excellent. Its also great to actually build it yourself rather than it being pre built!

joanne hudson (verified owner) –

The guys at oozenest we’re so helpful and helped me chose the correct program for my workbee

Avraham Czeisler (verified owner) –

I’m in the middle of the assembly process untill now…till now i’m impressed with the mechanical parts quality, they look good, have a very nice finish and a robust structure. The instructions are clear, logical and easy to understand and the parts are well packed. Well done!

Ashley Kitchen (verified owner) –

A well thought out product which is competing with the other open source brands

Mirco (verified owner) –

Fantastic kit well packaged. Will be a pleasure to build it

Oliver Plaado (verified owner) –

Really nice machine

Allan Walker (verified owner) –

Well packaged and everything very clearly labelled. Mechanical assembly went okay, although did struggle with some bits as items supplied didn’t match instruction booklet supplied, however was able to find updated instructions on line. This may be due to the change from belt to screw drive and the paperwork not quite catching up, just a comit it wasn’t a major problem. Did also find that we had some bits over which I think is due to the packets of screws etc cover all models and as our is at the smaller end of the range.

All in all very good.

ron parker (verified owner) –

superb kit, woks a treat

Felix (verified owner) –

Awesome product and best customer service.

Panayiotis Nikolaou (verified owner) –

Great product, easy to assemble, and very sturdy.

Ricardo Martin Gosalvez (verified owner) –

Well packed and all well served.

Romeo (verified owner) –

Very well packed and instructions were very clear. The machine does its job perfectly.

giraud nicolas (verified owner) –

very fast shipping, perfectly packaged!

Tom Helgesen (verified owner) –

very good. instructions was clear. one component in the kit was wrong, but all in all very good. the machine is not finished yet…

Geert Ceulemans (verified owner) –

Service! and that’s what the team delivers!

cs (verified owner) –

good capabilities for the price

Rich (verified owner) –

Great product, very robust.

Brian Woolford (verified owner) –

Brilliant product great help on phone

Alan Morris (verified owner) –

Superb quality kit with all items perfectly packed and labelled, and, believe me, there are a lot of them! A comprehensive construction manual, of good quality, meant that the build was completed in good time and was a pleasurable exercise. All the components were top quality and beautifully prepared. Make no mistake. the build demands concentration and care if the expected results are to be achieved but given the wealth of on-line support, YouTube videos and, if required, telephone support, you will be rewarded with a great machine at a very competitive price. If you can put together a typical Ikea product you will have no problems with the Workbee and be left wondering why multinationals cannot achieve similar results!

Mr Andy Gilchrist (verified owner) –

Excellent materials, well packed and delivered òn schedule. The individual items were all well bagged, labelled with a reasonable number of extras to cover the inevitable losses during construction.

The instructions were the most comprehensive I have seen and were in English not Chinglish.

Stuart Winstanley (verified owner) –

Not fully built it yet, but all the parts and well made and fit together perfectly. It looks a really solid machine and I look forward to finishing it and getting stuck in routing.

Mike NZ (verified owner) –

Early days, but seems sturdy and well made, as it should be for the price. Good videos, build manuals and ongoing development & support. I have Makita, as Dewalt was out of stock at the time of order. Hope your business thrives.

Jason M (verified owner) –

Good design, good quality parts

Robert_Sims (verified owner) –

Great machine at a great price

Sanjaya Sharma (verified owner) –

I looked all the places to find me a good CNC and this was the best machine I could find for this price with large work place, machine is very good solid built with 32 bit duet controller makes it far better than its class CNC machine. Also customer support is the best I seen anywhere. Thank You Ryan and Josh.

A. Necker (verified owner) –

It is my frist CNC machine.

It looks roubust and reliable. And the fact, that it is made mostly out of V-Slot rails, is great.

Makes it much easier to upgrade and mod something on!

The assembling was not so hard and cause less problems. Only one screw was deformed (no Hex hole).

A option for a 43mm euro spindle mount would be great.

But in my opinion is it a great machine that performs really well!

Arsen Sostar (verified owner) –

Really perfect cnc and easy to operate.